CUSTOM END-OF-LINE PACKAGING SOLUTIONSCombi is a worldwide provider of industrial packaging systems. We engineer and manufacture custom automated packaging systems, from semi-automatic to fully automatic packaging lines.Our packaging solutions provide the customization and flexibility required by customers to increase production . We’re ready to work with you to find the right system to fit your specific needs.

PACKAGING SOLUTIONSFind a full range of packaging solutions, including case erectors, tray formers, case sealers, case packers, ergonomic hand packing stations, robotic case erectors, robotic case packing and robotic palletizing systems.

Our custom automated packaging solutions serve a broad range of industries, providing dependable performance. We can engineer solutions for everything from basic lines to the most demanding applications. We’re able to meet specific requirements, including sanitary options for food manufacturers.

We can work with you, whether you’re one facility or a national corporation with high-capacity needs.

.jpg)

Video can’t be displayed

This video is not available.

Video can’t be displayed

This video is not available.

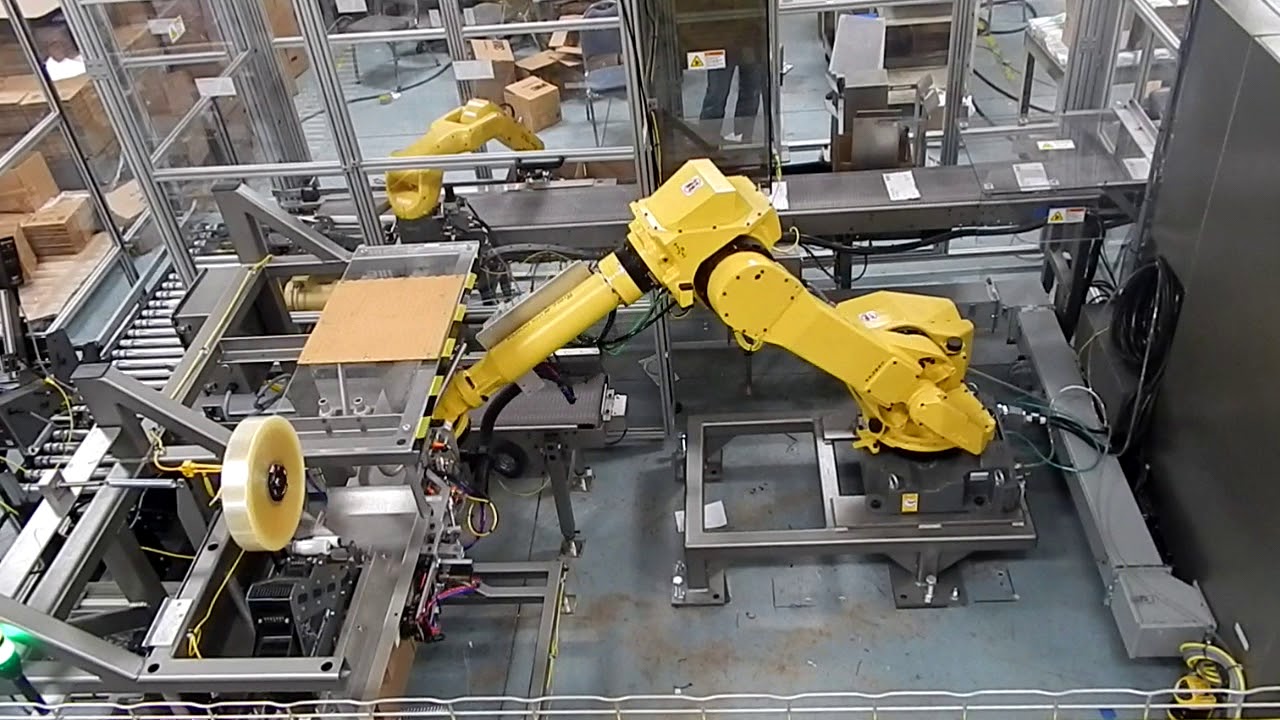

COMBI ERGOPAKPAL

ROBOTIC CASE PACKER AND PALLETIZER

Downsize your case packing and palletizing areas with a compact Combi ErgoPakPal. With a robotic case packer and a robotic palletizer, this system increases productivity while using minimal floor space.Equipped with an endless array of custom end effectors, the ErgoPakPal robotic case packer can safely handle just about any product that goes into a corrugated shipping case. A robotic palletizer equipped with a FANUC robot completes the end-of-line packaging cell. Our engineers are experienced in integrating other OEM equipment into our case packing or palletizing lines like pamphlet inserters, weigh stations, and case labelers, providing even more efficiency.

FEATURESBelow is a list of the features that are included standard, please request a quote to learn how our engineers can design a custom robotic packaging machine to fit your specific needs. The versatile ErgoPakPal is fully customized to fit available floorspace and includes:

- Automatic Case Erector

- Product Accumulation

- Case Packing Station

- Product Infeed Conveyor

- Case Sealer with adhesive tape or hot melt glue

- Case Transfer Conveyor

- Case Stacking Station

For short runs of product or product seldom produced, the case packing station allows for optional manual case packing, giving you additional flexibility on your packaging line.

Video can’t be displayed

This video is not available.

COMBI ERGOBOT

ROBOTIC PICK AND PLACE PACKING STATION

Increased global competition is driving leaner operating efficiency in today's manufacturing plants. To gain efficiencies, robots are being used more frequently in more and more plants for case packing and palletizing because of the increased throughput, vision and cost savings today's robotic technology offers. These same plants are finding that human workers can work right alongside robots, with proper guarding, as they each perform a task for which they are best suited.

Combi Packaging Systems offers a Robotic Pick and Place Packing feature to fully automate case packing operations that may require verifying lot or serialization numbers, varying pack counts, creating retail ready packages, or automating tasks that are difficult or unsafe for humans.

For greater flexibility and greater throughput, the Fanuc robot can be used during times when hand packing is unavailable or impractical.

Combi Packaging Systems offers a Robotic Pick and Place Packing feature to fully automate case packing operations that may require verifying lot or serialization numbers, varying pack counts, creating retail ready packages, or automating tasks that are difficult or unsafe for humans.

For greater flexibility and greater throughput, the Fanuc robot can be used during times when hand packing is unavailable or impractical.

BENEFITSBelow is a list of the features that are included standard, please request a quote to learn how our engineers can design a custom robotic packaging machine to fit your specific needs.

- Reduces labor expense

- Provides higher rate of throughput - can run 24 hours a day

- Provides traceability of products, enabling better tracking and isolation of contaminated products

- Easy case packing of varying pack counts, variety packs, retail ready packages

- Greater precision and consistency, minimizes waste and reduces product loss due to damage

- Removal of human interaction in hazardous environments, reduces workplace injuries

REQUEST MORE INFO OR QUOTE BELOW