SLITTERS, SHEETERS, REWINDERS, and STACKERS

Every Rosenthal Sheeter, Slitter, Roll Slitter, Slitter Rewinder, Stacker or Custom Converting System is the product of a team effort. Sales, engineering, assembly and management are driven by the customer-centered philosophy that has guided Rosenthal Manufacturing for 3 generations. While our customer s specific needs have changed over the years, our commitment to providing high-quality, reliable solutions has remained constant.

Send us a sample roll of your material and we will gladly test it for you on one of our sheeters, slitters, roll slitters, slitter rewinders, stackers or custom converting systems: adhesive vinyl, tape, premask, wovens, non-wovens, banner, awning, tent, fabric, leather, suede, film, foam, foam tape,felt, gasket, rubber, paper, PVC, polyester, polyethelene, polyurethane, copper foil, prepreg, PVB, EVA, paper and many other materials are just some of the materials that thousands of happy customers are converting on their Rosenthal Sheeters, slitters, roll slitters, slitter rewinders and stackers.

Video can’t be displayed

This video is not available.

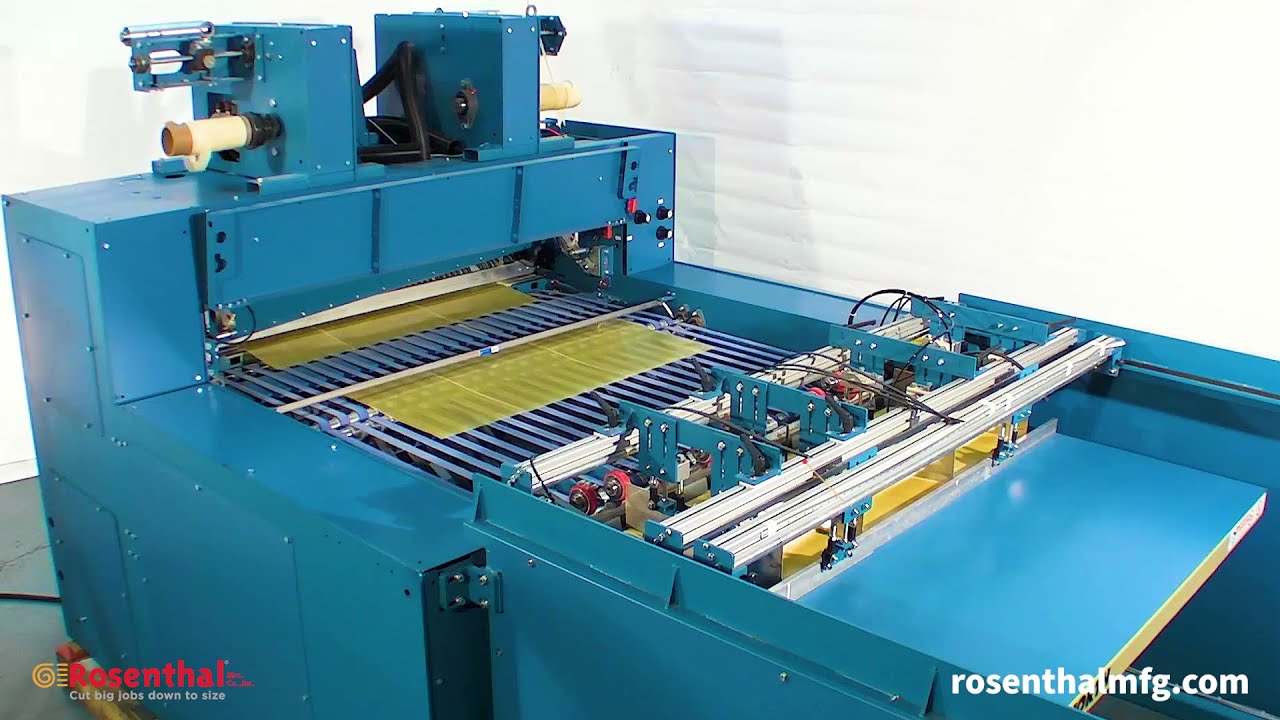

Optional slitting gives you the ability to cut to length and width in a single process.

The proprietary scissors action up cut shear cutting mechanism is virtually maintenance free and delivers a clean cut on a wide variety of materials.

Video can’t be displayed

This video is not available.

Intuitive controls and a color touchscreen make operating the RCS Sheeter a breeze.

The proprietary scissors action shear cutting mechanism is virtually maintenance-free and delivers a clean cut on a wide variety of materials Add an output conveyor to assist carrying cut sheets away from the machine A lowering table and automatic stacker are also available.

An all-welded heavy-duty steel frame means your sheeter will be tough enough to handle just about anything you throw its way and deliver years of dependable service.

Optional slitting gives you the ability to cut to length and width in a single process The RCS sheeter is built to order and is available in various web width and master roll capacities. Additional features such as punching, decurling, rewinding, and cut to mark are available.

Designed and built in the USA, the RCS Sheeter is the perfect choice to satisfy your in-house sheeting and slitting requirements.

Additional functionality includes Conveyor Stacker, watch the video to the right to see it in action.

*** See other compatible products such as the Shear up cut lowering table

Disclaimer: *Specifications are subject to change. Performance is material dependent Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information.

Video can’t be displayed

This video is not available.

Equipped with multiple roll stands lets you increase production by running multiple layers or reduce down time for material changeovers by having additional materials preloaded.

Intuitive controls and color touchscreen make operating the RCS sheeter a breeze.

The proprietary scissors action shear cutting mechanism is virtually maintenance free and delivers a clean cut on a wide variety of materials Add an output conveyor to assist carrying cut sheets away from the machine A lowering table and automatic stacker are also available.

The RCS sheeter is built to order and is available in various web width and master roll capacities. Additional features such as slitting, punching, decurling, rewinding and cut to mark are available.

Designed and built in the USA, the RCS Sheeter is the perfect choice to satisfy your in-house sheeting and slitting requirements.

Disclaimer: *Specifications are subject to change. Performance is material dependent Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information. We recommend sending sample rolls of your material for testing the suitability of this system. Material sent for testing is at the sender's expense and risk.

Video can’t be displayed

This video is not available.

The proprietary scissors action down cut shear cutting mechanism is virtually maintenance free and delivers a clean cut on a wide variety of materials. An output conveyor assists in carrying cut sheets away from the machine Add a lowering table or automatic stacker for greater efficiency.

With the RCH you can quickly and accurately convert rolls into any length sheets you need The RCH comes standard with PLC control, Color Touch Screen HMI and vector drive for accurate feeding, upgrade to a servo for the highest precision.

Optional slitting gives you the ability to cut to length and width in a single process.

The RCH is built to order and is available in various web width and unwind capacities Additional features such slitting, decurling, rewinding and cut to mark are available.

Disclaimer: *Specifications are subject to change. Performance is material dependent Please request a quotation for the latest information

Video can’t be displayed

This video is not available.

The heavy duty reciprocating cross cutting mechanism delivers a clean cut on a wide variety of materials.

With the RCX you can quickly and accurately convert rolls into any length sheets you need. Optional slitting gives you the ability to cut to length and width in a single process.

The RCX is built to order and is available in various web width and unwind capacities Additional features such slitting, decurling, rewinding and cut to mark are available.

*** See other compatible products such as the Mobile Roll Stand

Disclaimer: *Specifications are subject to change. Performance is material dependent Please request a quotation for the latest information

Video can’t be displayed

This video is not available.

The proprietary scissors action shear cutting mechanism is virtually maintenance free and delivers a clean cut on a wide variety of materials.

Optional slitting gives you the ability to cut to length and width in a single process. The RCS is built to order and is available in various web width and unwind capacities. Additional features such slitting, decurling, rewinding and cut to mark are available.

Disclaimer: *Specifications are subject to change. Performance is material dependent. Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information. *Specifications are subject to change. Performance is material dependent Machine stops to cut, maximum feed speed is effected by material characteristics. We recommend sending sample rolls of your material for testing the suitability of this system. Material sent for testing is at the sender's expense and risk.

Video can’t be displayed

This video is not available.

The proprietary scissors action down cut shear cutting mechanism is virtually maintenance-free and delivers a clean cut on a wide variety of materials.

With the RCH you can quickly and accurately convert rolls into any length sheets you need. Optional slitting gives you the ability to cut to length and width in a single process.

The RCH is built to order and is available in various web width and unwind capacities. Additional features such slitting, decurling, rewinding and cut to mark are available.

Disclaimer: Specifications are subject to change. Performance is material dependent. Maximum feed speed and accuracy is effected by material characteristics. Please request a quotation for the latest information..

Video can’t be displayed

This video is not available.

The Rosenthal RS Manual Roll Slitter is the perfect solution for quickly slitting wide rolls into narrower rolls. Our machines come with various options that improve your particular project.

Lock your roll into place with the patented expansion ring. Position the proprietary blade holder and quickly slit through your roll.

Go layer by layer down through the core without unwinding and rewinding. This process eliminates time-consuming setups.

An all-welded heavy-duty steel frame means your roll slitter will be tough enough to handle just about anything you throw its way. It will deliver years of dependable service.

The RS roll slitter is built to order and is available in various web width and OD capacities.

Additional features such as rewinding and dual blade configurations are available.

Designed and built in the USA, the Rosenthal RS roll slitter is the perfect choice to quickly, inexpensively and safely slit your stock width rolls into any width you need.

Disclaimer: *Specifications are subject to change. Performance is material-dependent. Please request a quotation for the latest information. We recommend sending a full OD sample roll of your material for testing the suitability of this system. Material sent for testing is at the sender's expense and risk.

Video can’t be displayed

This video is not available.

Lock your roll into place with the patented expansion ring, position the proprietary blade holder and quickly slit through your roll, layer by layer down through the core without unwinding and rewinding, eliminating time consuming setup.

Load a roll onto the unwind and place an empty core on the mandrel and you can rewind all or a portion of your master roll.

An all welded heavy duty steel frame means your roll slitter will be tough enough to handle just about anything you throw its way and deliver years of dependable service The RSW is built to order and is available in various web width and OD capacities. Additional features such as cantilevered unwind and dual blade configurations are available.

Disclaimer: *Specifications are subject to change. Performance is material-dependent. Please request a quotation for the latest information. We recommend sending a full OD sample roll of your material for testing the suitability of this system. Material sent for testing is at the sender's expense and risk.

Video can’t be displayed

This video is not available.

The RSB quickly slits through rolls, layer by layer down through the core without unwinding and rewinding, eliminating time consuming setup.

The RSB can be equipped with various band blades or a diamond blade to slit a wide variety of materials.

The RSB is built to order and is available in various web width and OD capacities. Additional features such as rewind and dual blade con gurations are available.

Disclaimer: *Specifications are subject to change. Performance is material-dependent. Please request a quotation for the latest information. We recommend sending a full OD sample roll of your material for testing the suitability of this system. Material sent for testing is at the sender's expense and risk.

Video can’t be displayed

This video is not available.

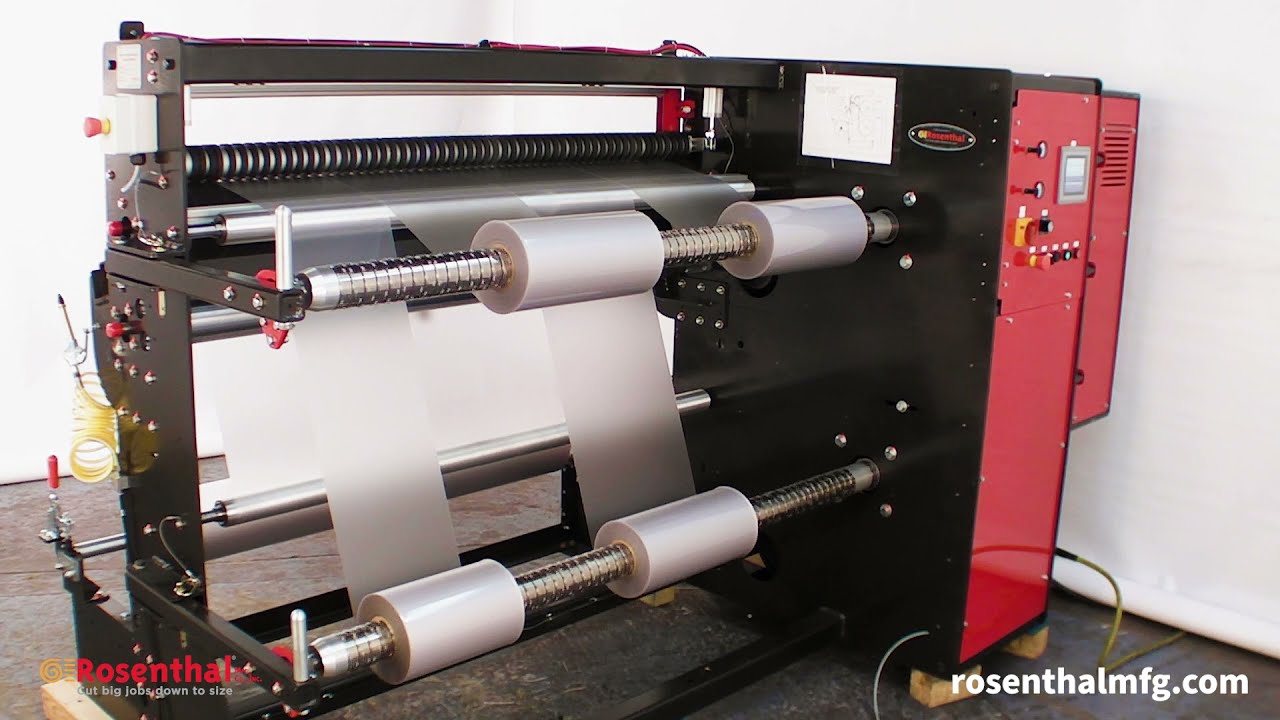

ControlsIntuitive controls and color touchscreen make operating the SRD a breeze. Our advanced tension control system comes with differential rewind shafts. They allow the SRD to smoothly and consistently rewind a wide variety of laminates.

MaterialsIt handles prepregs, foils, fabric, non-wovens, paper, film, and many other specialty materials. These materials see use with flexible packaging.

Additional features that are available include:- Lay on rollers- Auto cut-offThe SRD can also be equipped with razor, score or shear slitting. These options are designed to meet your requirements for edge quality and budget. Designed and built in the USA, the SRD Slitter Rewinder Machine is the perfect choice to satisfy your in-house slitting and rewinding requirements.

Disclaimer: *Specifications are subject to change. Performance is material dependent Please request a quotation for the latest information.

Video can’t be displayed

This video is not available.

With the Rosenthal Gripper Stacker, you can quickly and accurately stack the output of your Sheeter. Optional indexing conveyor gives the ability to reduce downtime for changing out stacks.

Disclaimer: *Specifications subject the change. Speed, Accuracy, Sheet Length are material dependent. Maximum feed speed is reduced by Gripper Stacker. Feed Length is limited by Gripper Stacker Length. Please send samples rolls of your material to verify suitability. Please request a proposal for the latest specifications.

Video can’t be displayed

This video is not available.

With the Rosenthal Pick and Place, you can quickly and accurately stack or position the output of your Sheeter. Optional indexing conveyor gives the ability to reduce downtime for changing out stacks.

Disclaimer: *Specifications subject the change. Speed, Accuracy, Sheet Length are material dependent. Maximum feed speed is reduced by Gripper Stacker. Feed Length is limited by Gripper Stacker Length. Please send samples rolls of your material to verify suitability. Please request a proposal for the latest specifications.

Disclaimer: Specifications are subject to change. Performance is material dependent. Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information.

Video can’t be displayed

This video is not available.

Disclaimer: Specifications are subject to change. Performance is material dependent. Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information.

Video can’t be displayed

This video is not available.

Disclaimer: Specifications are subject to change. Performance is material dependent. Machine stops to cut, maximum feed speed is effected by material characteristics. Please request a quotation for the latest information.