Video can’t be displayed

This video is not available.

- Power to weight ratio offers easy handling and maneuvering, even for the tightest radius

- Low-profile baseplate and narrow silhouette standard make cutting of intricate patterns and tight turns simple

- Perfect fit and continuous running with cross heads, crank and knife slides that are machined to a tolerance within .0005″(0.0013cm)

- Simple handling of the machine due to its low center of gravity

- Low maintenance requiring only daily lubricating with the easy-to-use One Shot single-reservoir oiling system.

- Engineered with a low profile, polished and streamlined baseplate designed to reduce friction and distortion of material, regardless of the number of plies

- Constructed of superior quality materials to ensure durability and longevity

- Motor is designed and manufactured to efficiently disperse heat away from the operator

- Designed to cut out patterns, as well as straight lines in multiple thicknesses of material

- Motor housing incorporates a single-reservoir oiling system which eliminates the need to oil during a work shift

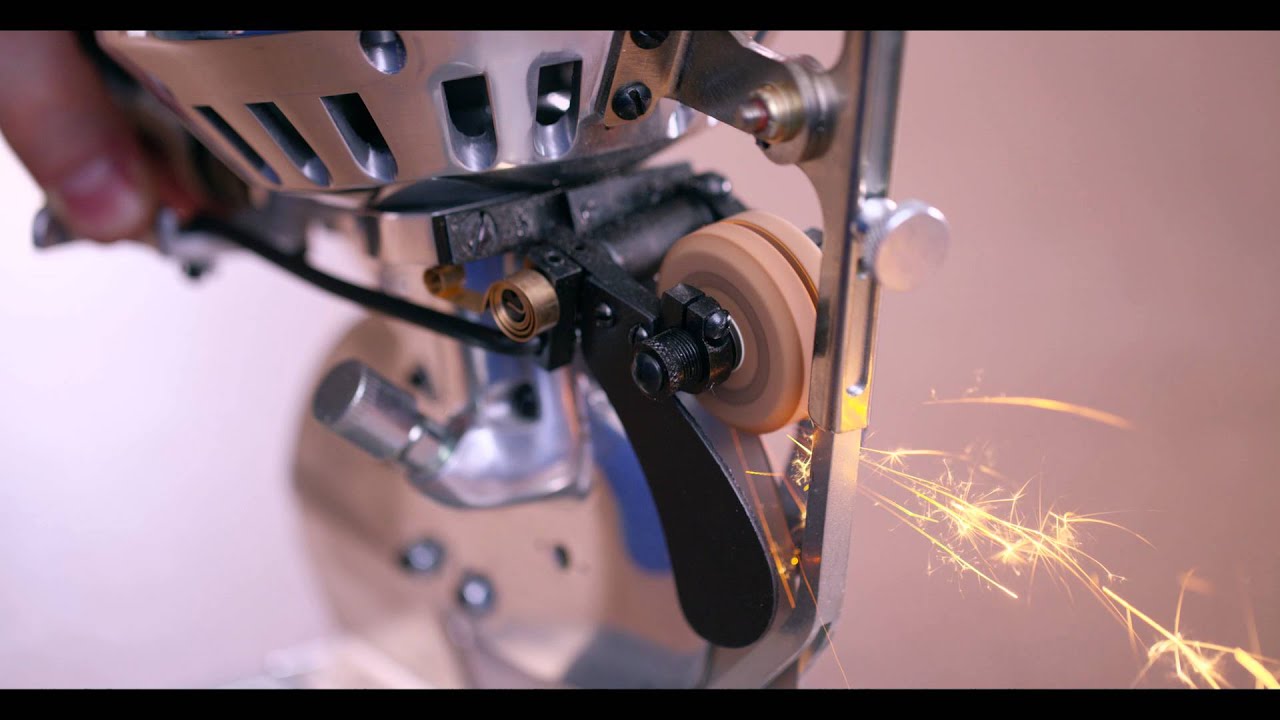

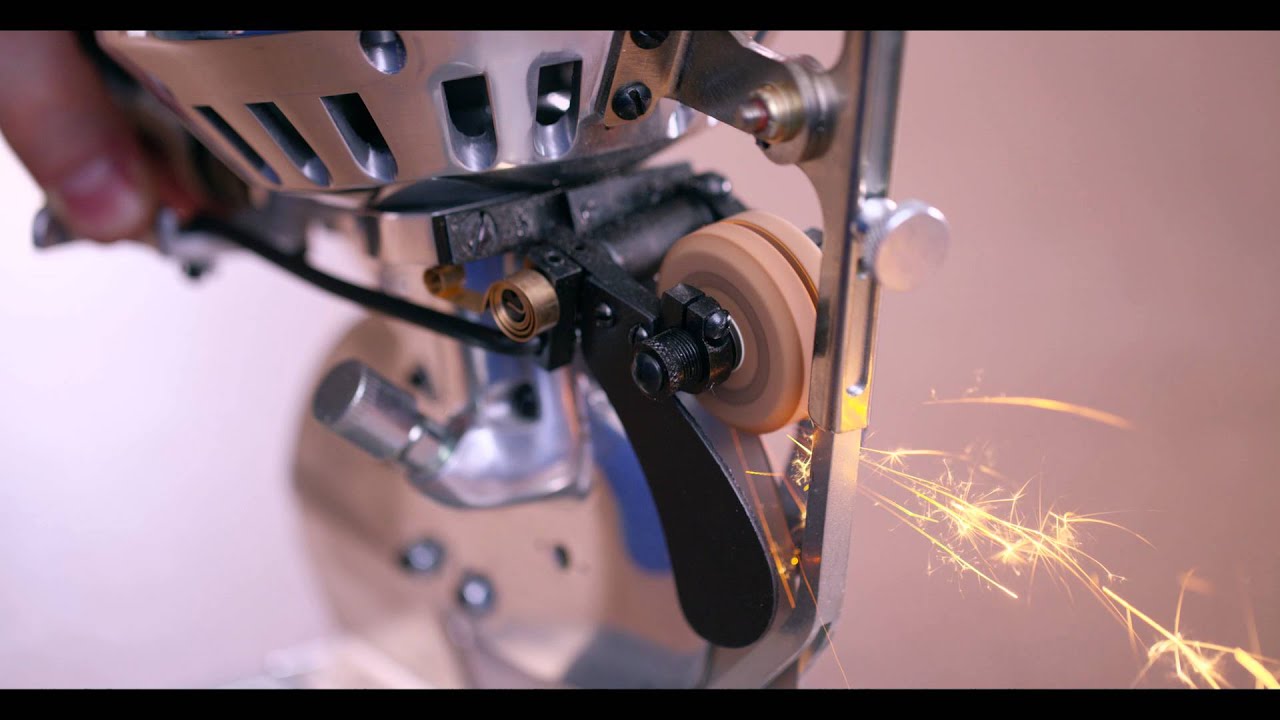

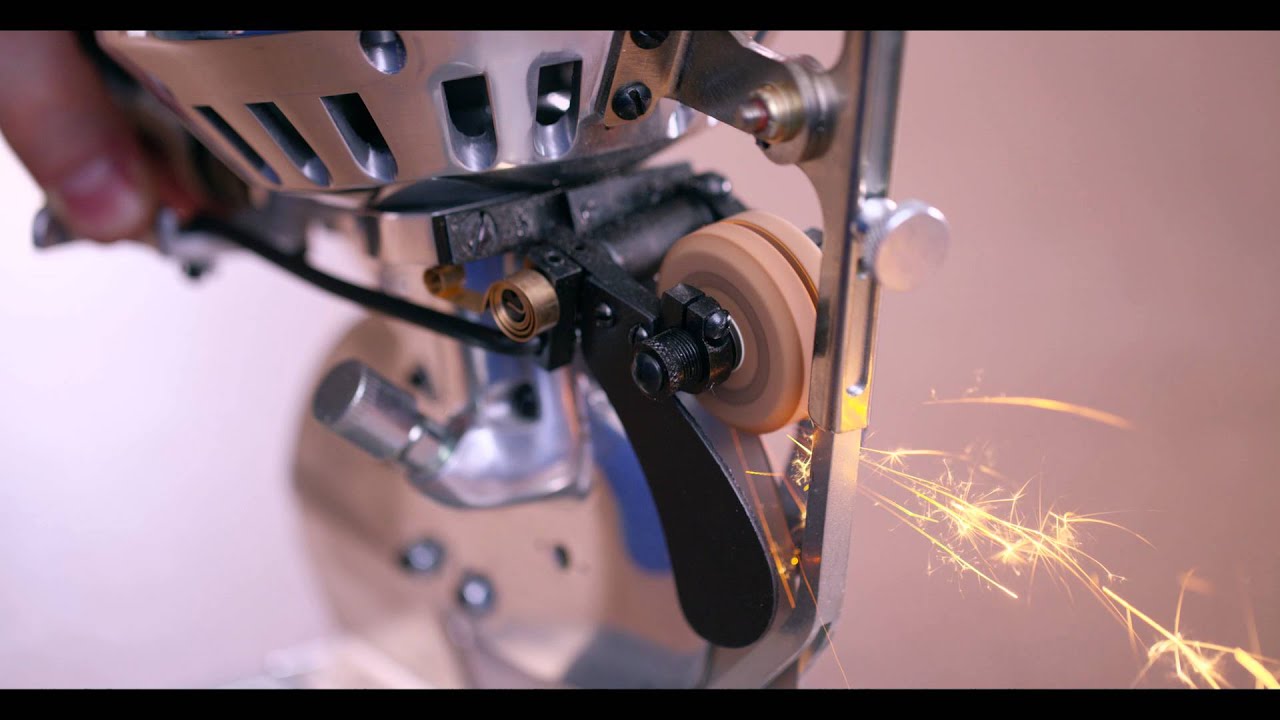

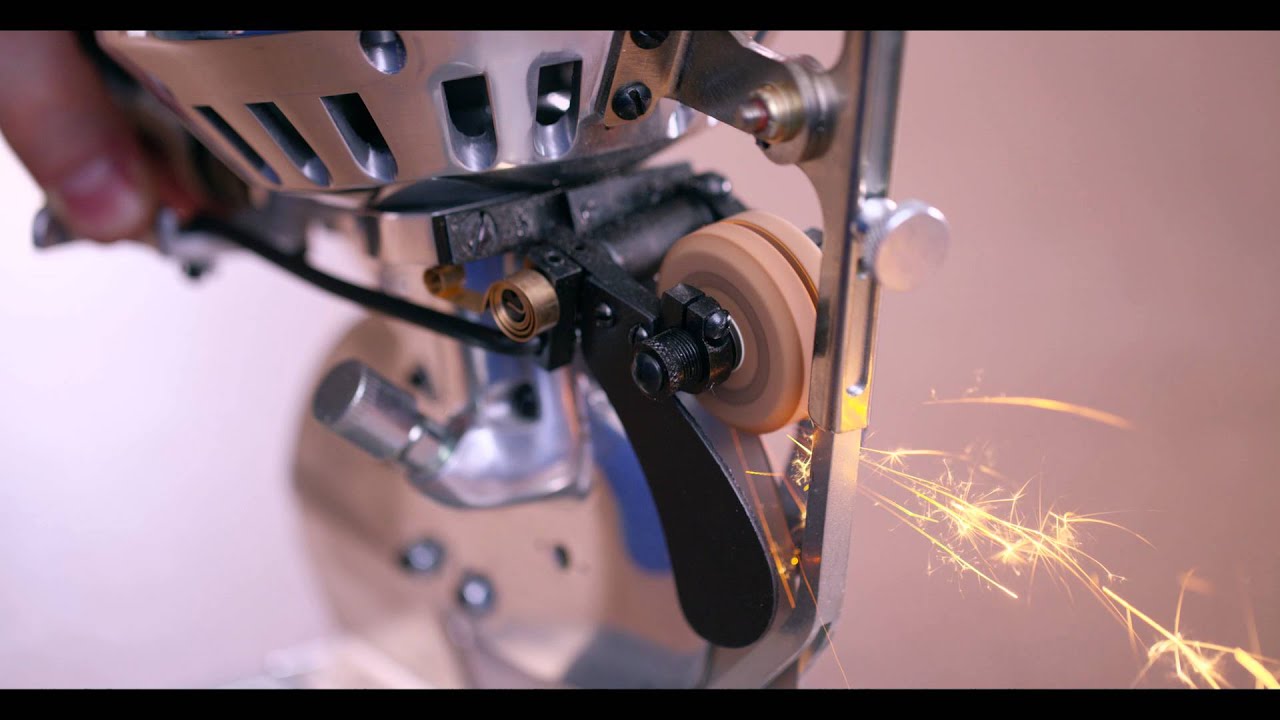

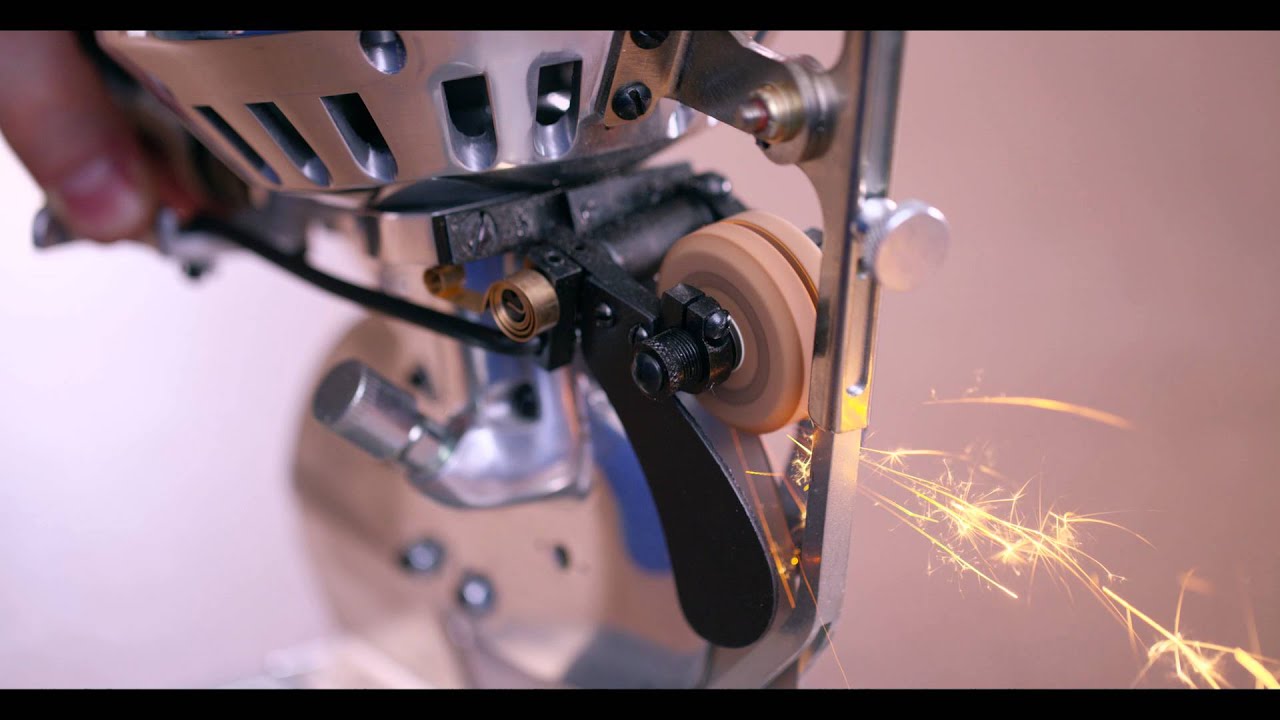

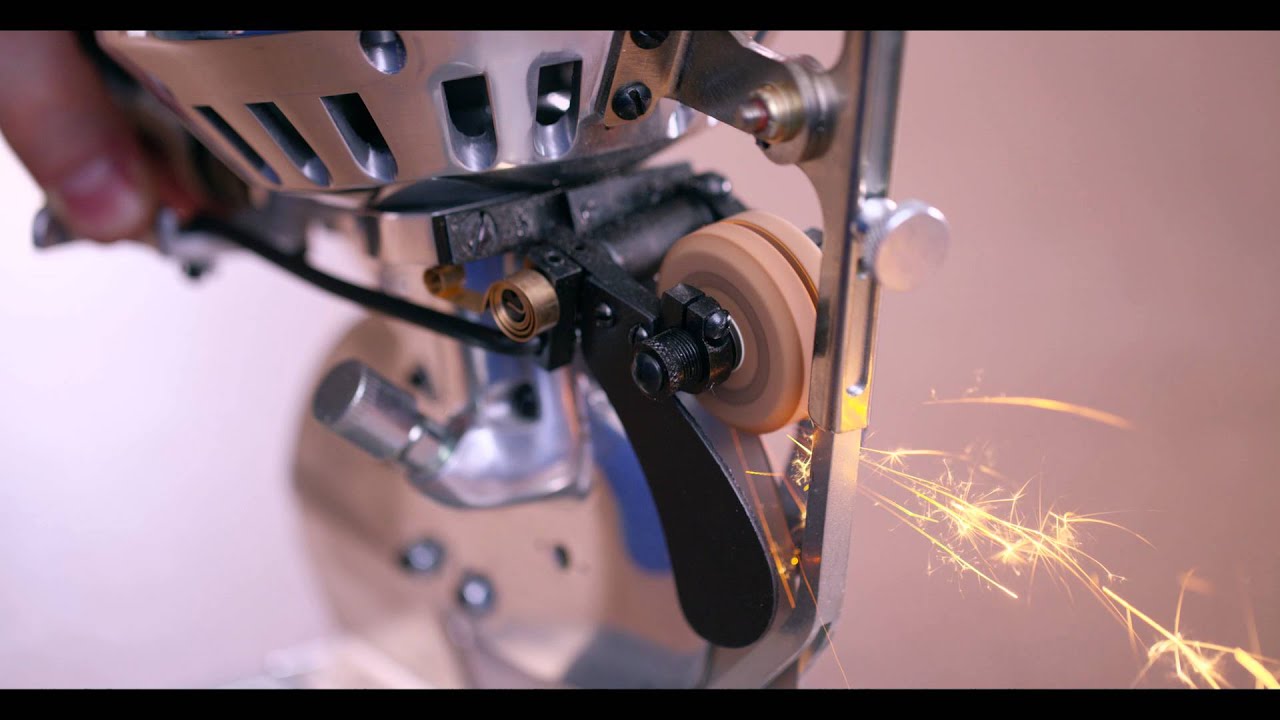

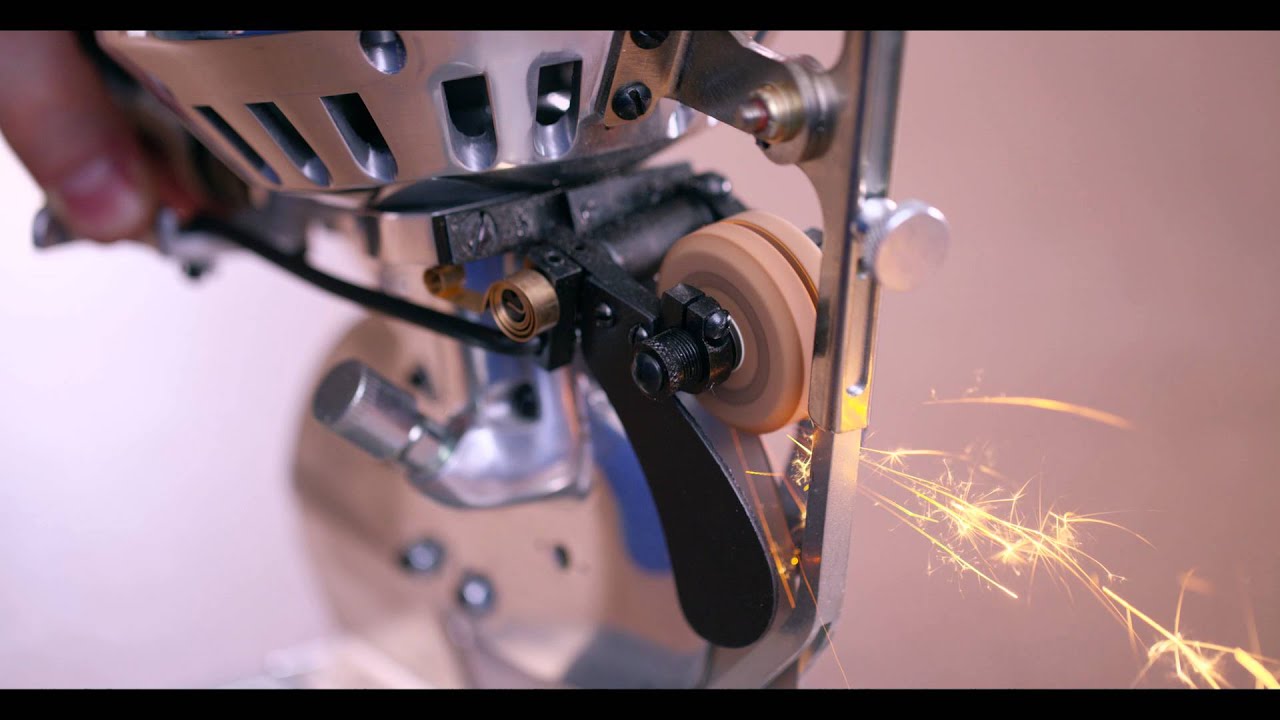

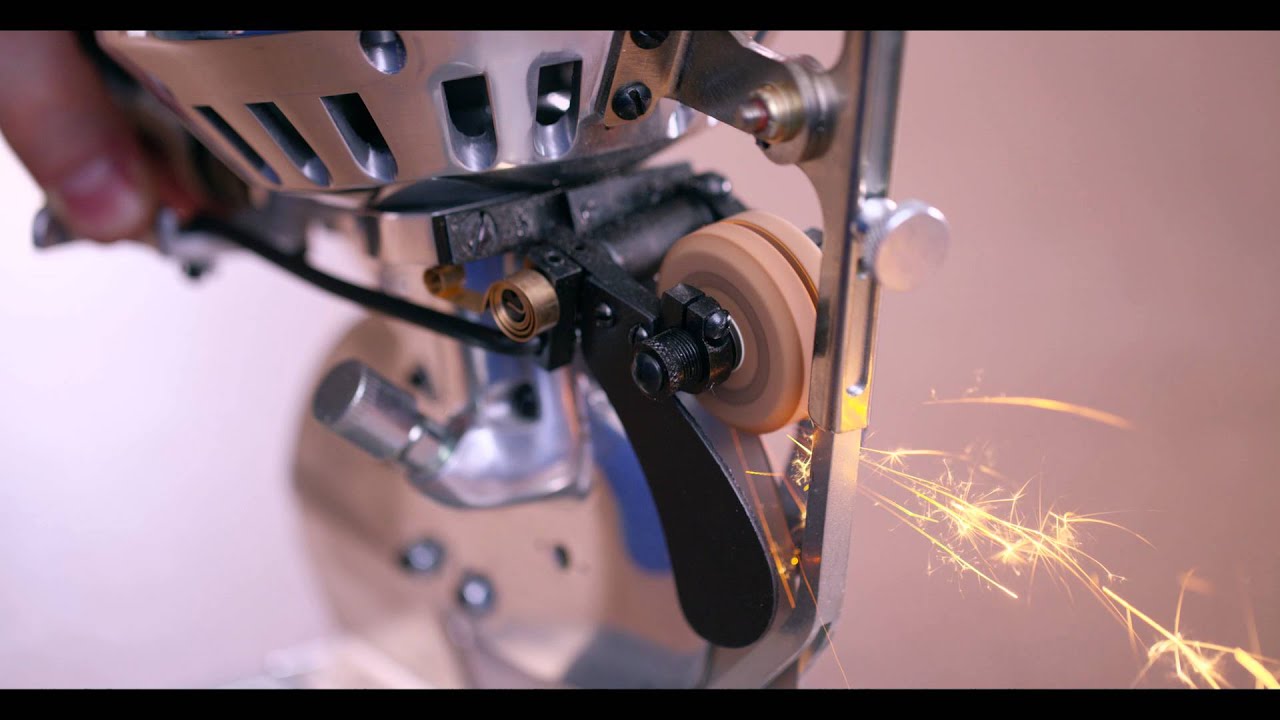

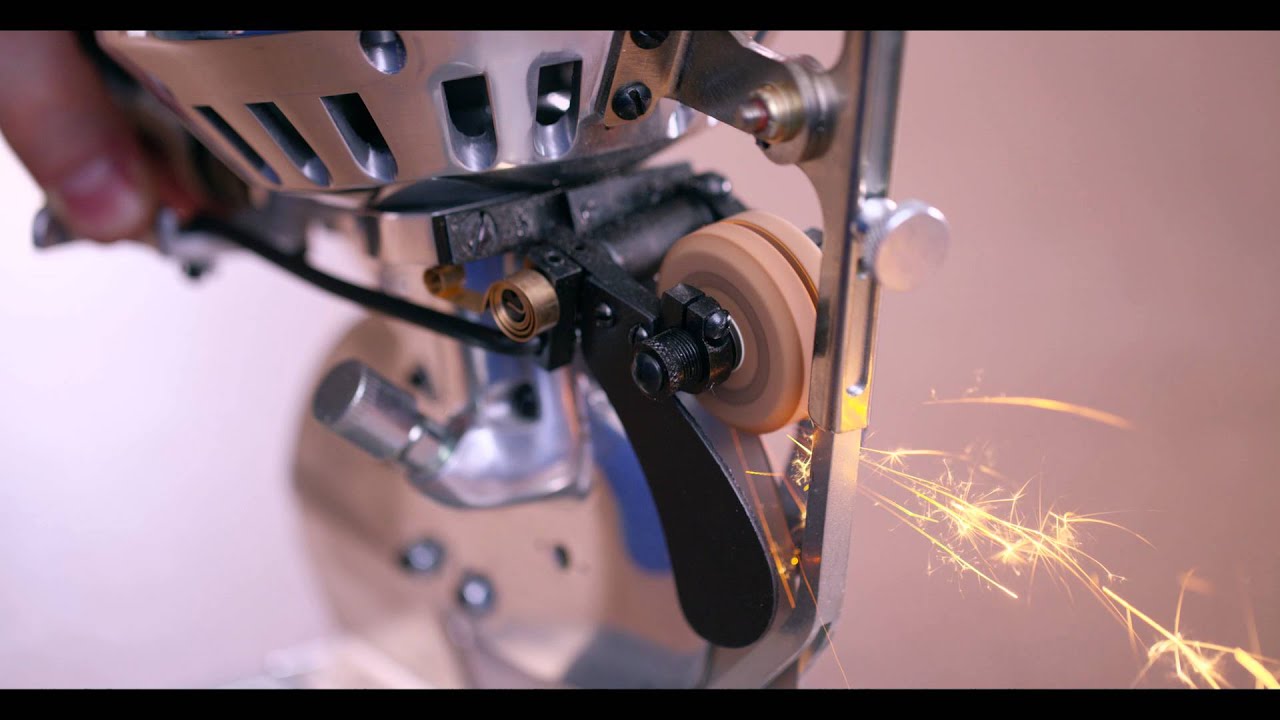

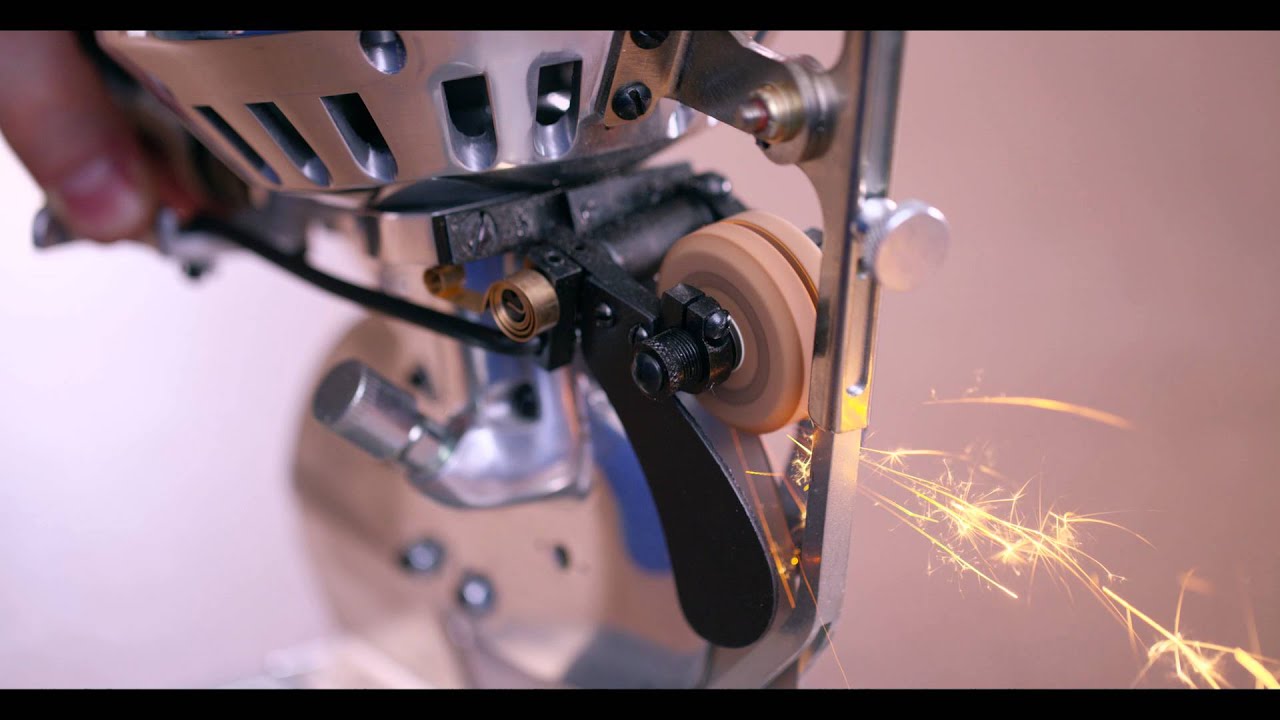

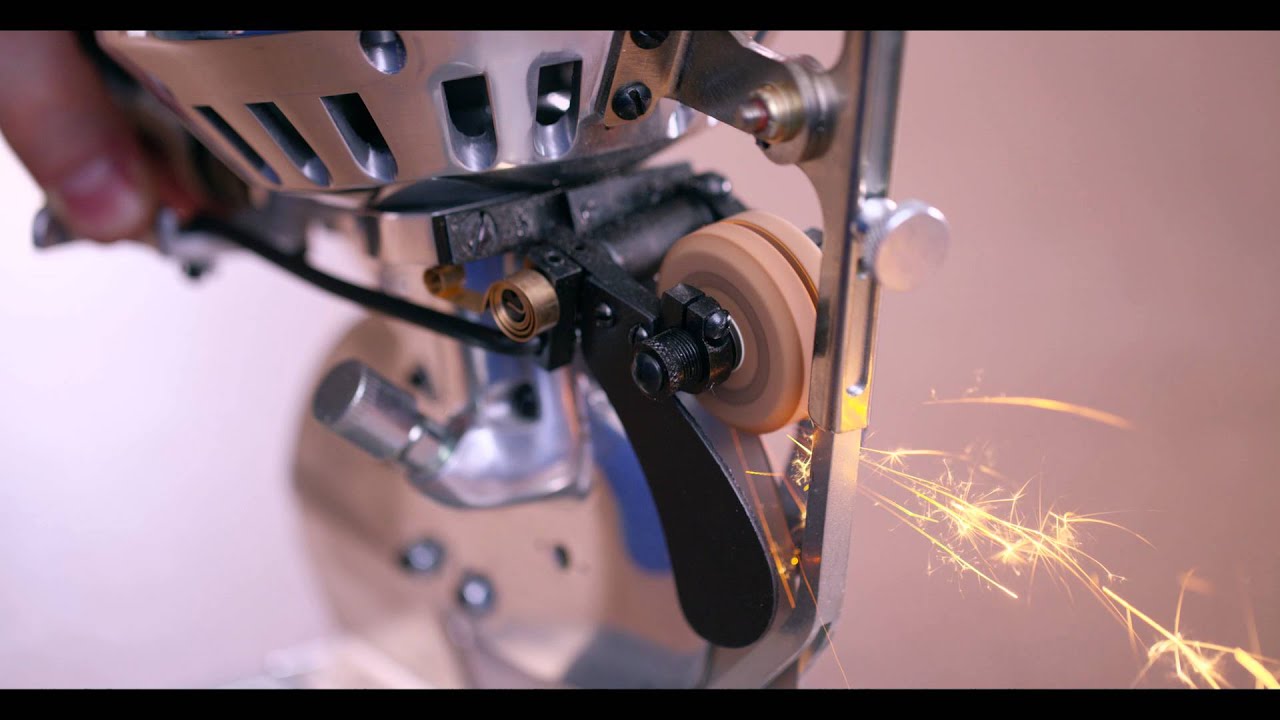

- One-touch automatic sharpener to keep the blade razor sharp

- Machines are available in eight different heights (5 in. – 13 in. / 12.7 cm – 33 cm), designed for different cutting applications; the lower the machine, the easier it is to maneuver.

Video can’t be displayed

This video is not available.

The model 627X is Eastman’s most powerful straight knife cutting machine and is available in the same sizes, strokes, and electrical configurations as the standard Blue Streak II cutting machine.

All Eastman cutting machines are built with the highest grade materials available.

- The Straight Knife Cutting Machine has an extra powerful motor, nearly twice the horsepower of the standard Blue Streak II model, up to 2.2hp

- Designed to cut the toughest flexible materials and/or an increased number of ply

- Available in the same sizes, strokes and electrical configurations as the standard Blue Streak II cutting machine

Video can’t be displayed

This video is not available.

It is the only cloth cutting machine on the market that runs at 4,000 RPM’s. All Eastman cutting machines are built with the highest grade materials available.

- Features a variable speed motor to offer increased acceleration and smoother operation across a range of materials

- Runs at speeds of 1,200 to 4,000 RPM

- Heavy-duty performance for cutting extra heavy cloth or an increased number of ply

- Cutting of intricate patterns and tight turns due to the low-profile baseplate and narrow silhouette standard

- Available in the same sizes, strokes and electrical configurations as the standard Blue Streak II model

Video can’t be displayed

This video is not available.

All Eastman machines are built with the highest grade materials available.

- Heat reducing features such as a dual speed motor, short stroke and wave blade reduce blade contact by 80%

- Special gravity feed moistening attachment to eliminate fusing

- Coolant flow can be adjusted to achieve the desired degree of lubrication and cooling required

Video can’t be displayed

This video is not available.

The Micro Fog™ is available in a standard version, 629XMF, and a heavy-duty version, 627XMF.

All Eastman machines are built with the highest grade materials available.

- Ensures maximum heat reduction to eliminate fusing of materials aided by its dual speed motor, short stroke and wave blade

- The Micro Fog device sends a pressure fed mist of coolant / lubricant behind the knife and out through a specially slotted knife-slide to evenly cool the entire blade

- Requires 90-120 psi (6.2-8.3 bars) compressed air

Video can’t be displayed

This video is not available.

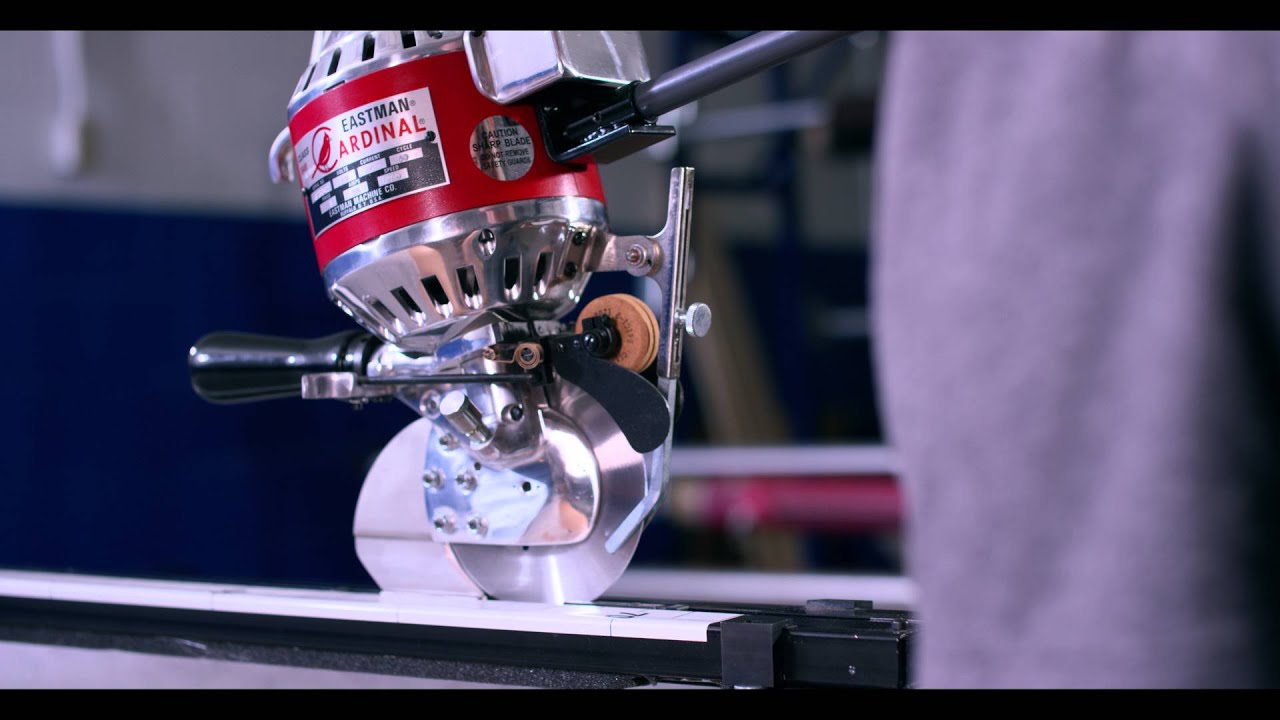

Eastman round knife machines are ideally suited for cutting large radius curves, straight lines and are applicable for a wide range of difficult to cut materials.

Video can’t be displayed

This video is not available.

All Eastman machines are made with the highest quality materials available.

- Heavy-duty motor with increased torque and cutting capacity

- Ideal for general purpose cutting of flexible goods such as industrial-grade materials and composites

- Blades are available in carbon steel, high speed steel, slotted, grooved and PTFE coated

Video can’t be displayed

This video is not available.

All Eastman machines are made with the highest quality materials available.

- Heavy-duty motor with increased torque and cutting capacity

- Ideal for general purpose cutting of flexible goods such as industrial-grade materials and composites

- Blades are available in carbon steel, high speed steel, slotted, grooved and PTFE coated

Video can’t be displayed

This video is not available.

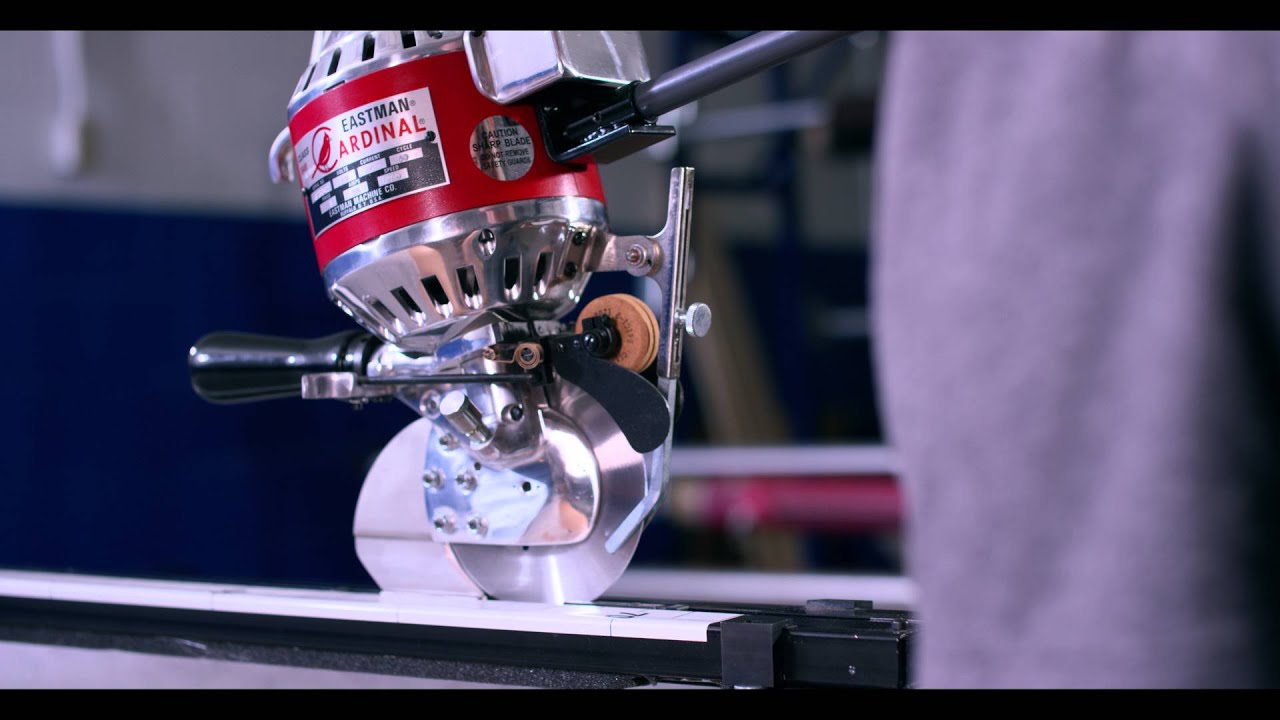

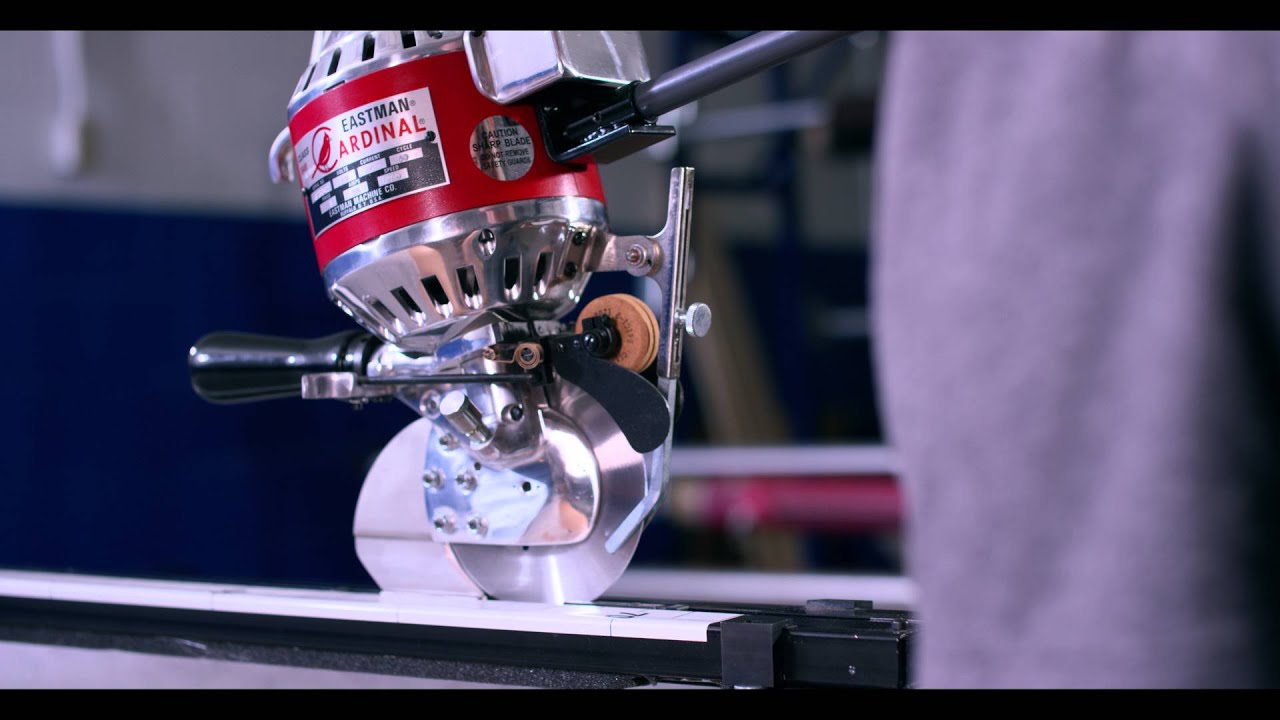

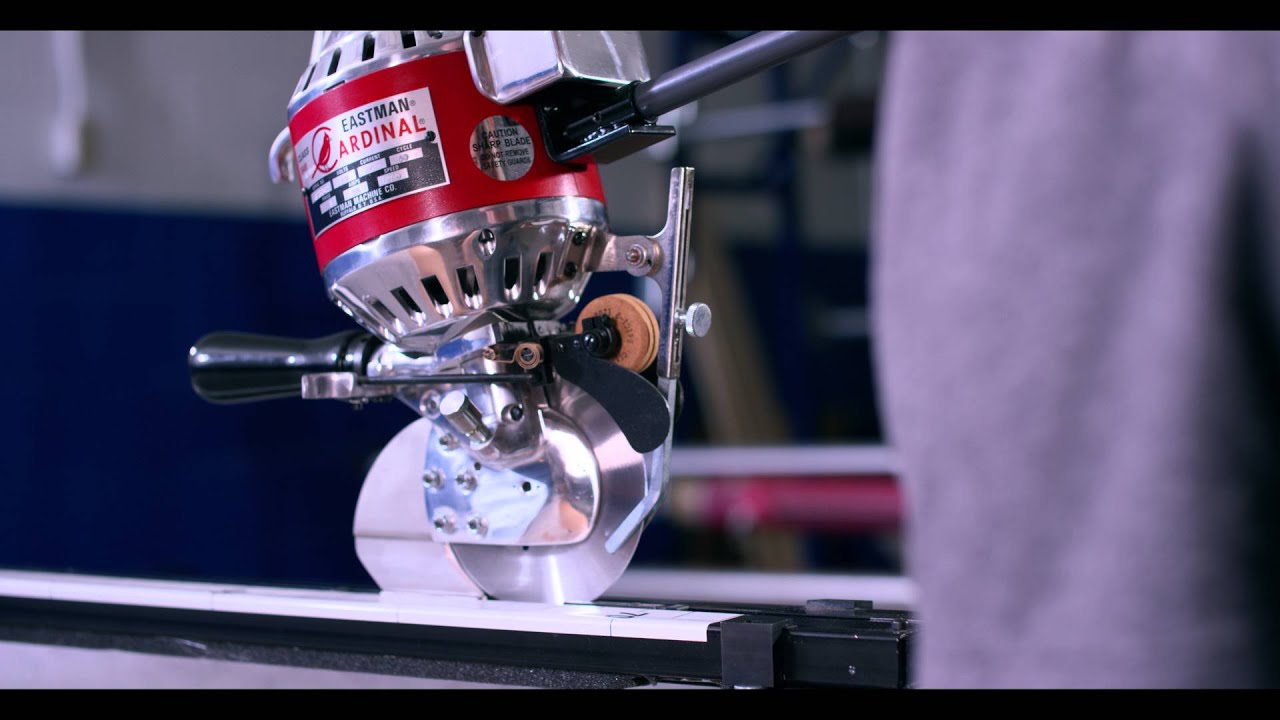

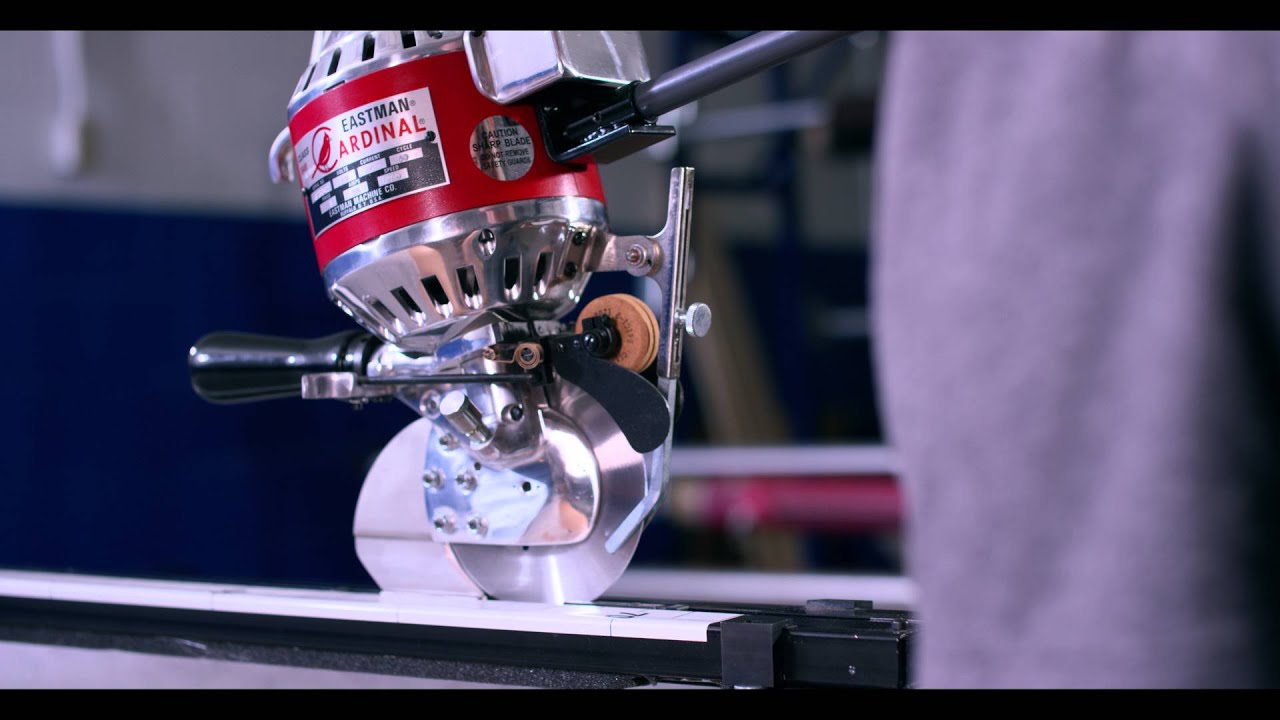

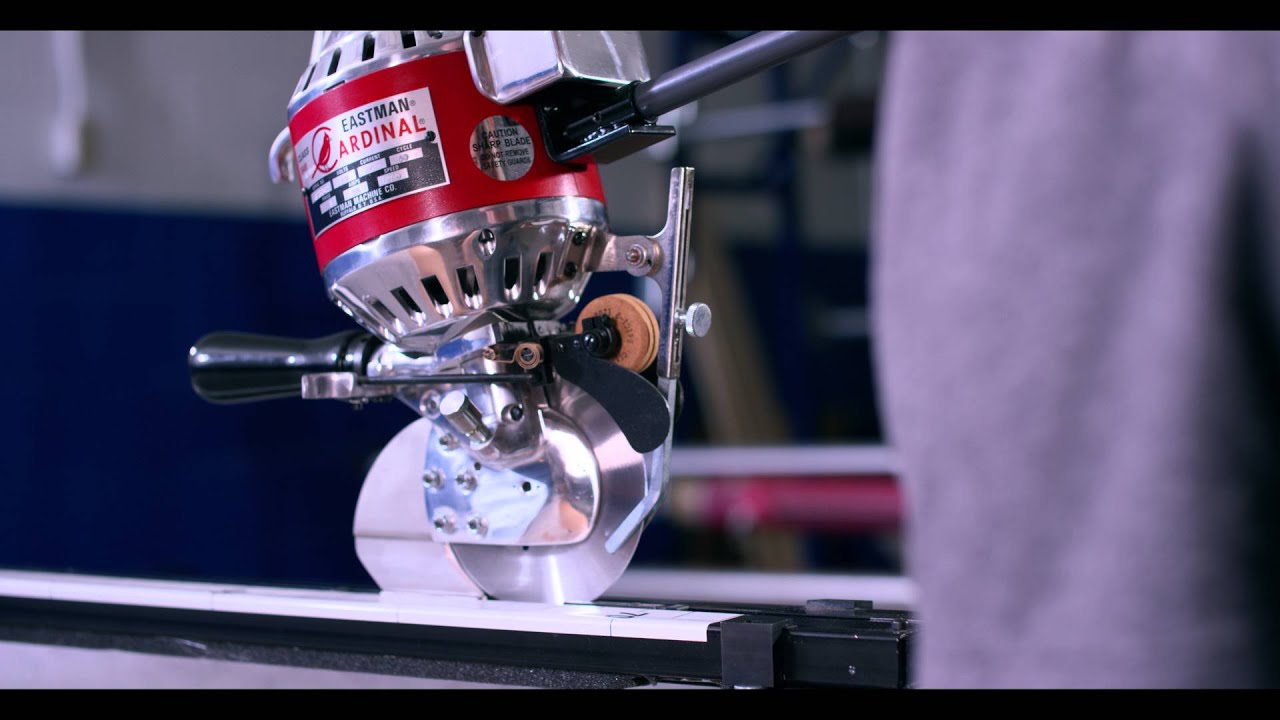

Like all Eastman round knives, the Lighweight Cardinal® is perfect for cutting large radius curves and straight lines.

All Eastman machines are built with the highest grade materials.

- The smallest round knife machine

- Lightweight maneuverability with power for cutting low plies

- Great for wool, cotton, silk, synthetics and various technical textiles

Video can’t be displayed

This video is not available.

The BK machines can be equipped with a standard roller base plate or with mounting brackets that allow the machine to be mounted for overhead support.

The standard narrow profile allows for clean slitting and snag-free material flow.

All Eastman machines are built with the highest quality materials available.

- May be mounted in a stationary position, on a frame or with a standard baseplate for slitting

- Narrow profile allows for clean slitting and snag-free material flow

Video can’t be displayed

This video is not available.

Each of these special Cardinal® round knife machines may be supplied with a high speed, low speed, or dual speed motor for the broadest range of applications. Both models may be fitted with an optional Plastic Master lubricator.

All Eastman machines are manufactured with the highest grade materials.

- Designed to easily cut through high durometer rubber, plastic sheeting and dense, flexible materials

- Has a powerful motor and additional cutting capacity

Video can’t be displayed

This video is not available.

The blade is grooved to reduce heat and allow the blade to shed carpet backing. The blades can also be coated for maximum heat reduction and the ability to eliminate build up of cut material.

All Eastman cutting machines are built with the highest grade materials available.

- Designed to cut through most pile types and backings

- Allows for cutting along and against the grain in curves, or straight edges

- Blade is grooved to reduce heat

- Reduced operator fatigue with the option of a long handle, where cutting can be done while seated

Video can’t be displayed

This video is not available.

The Plastic Master adapts to all Cardinal® series round knives.

All Eastman machines are built with the highest grade materials available.

- Attachment available for all Cardinal Round Knives

- Plastic Master Cooling/Moistening device plus a special notched blade reduce friction and heat to eliminate fusing of temperature sensitive materials

Video can’t be displayed

This video is not available.

This machine is an economical alternative for cutting through fine fabrics, such as low ply delicate synthetics, without pulls or damage to the material. The single-bevel 3 ¼ inch blade and shear plate provides a clean cut without fraying or unraveling material. The Gentle Giant, like all Eastman round knives, is perfect for cutting large radius curves and straight lines.

All Eastman machines are built with the highest grade materials available.

- Single-Bevel 3 ¼ in blade

- Eastman’s largest rotary shear

- High-torque universal motor maintains blade speed under heavy loads

- Cut through low-ply delicate synthetics without pulls or damage to the material

Video can’t be displayed

This video is not available.

This machine is an economical alternative for cutting through heavier weight materials, such as upholstery and industrial fabrics, and fine fabrics, such as low ply delicate synthetics, without pulls or damage to the material. The double-bevel 3 ¼ inch blade provides a clean cut and eliminates jamming between the blade and plate. The Little Giant, like all Eastman round knives, is perfect for cutting large radius curves and straight lines.

All Eastman machines are built with the highest grade materials available.

- Double-Bevel 3 ¼ in blade

- High-torque universal motor maintains blade speed under heavy loads

- Cut through heavier weight materials, such as upholstery and industrial fabrics, and low-ply delicate synthetics without pulls or damage to the material

Video can’t be displayed

This video is not available.

Model RS2 is equipped with a gravity fed blade lubrication and cooling system to eliminate materials from fusing. It boasts a high torque motor and is designed with a very low knife speed to keep friction and heat build-up to a minimum.

It is available with a base plate or strip gauge to cut strips with a tight tolerance.

All Eastman machines are built with the highest quality materials available.

- Engineered to cut very dense rubber and plastic sheeting

- Equipped with a high torque motor and variable knife speed

- Also available with baseplate only

Video can’t be displayed

This video is not available.

- Powerful, professional grade, cordless power tool weighing 4 lbs. (1.8 kg)

- Convenience and portability; battery powered

- Provided with two 20V (4ah) lithium-ion batteries – one for operation, one for charging

- Battery recharge time: 1 hour/battery

- The high torque motor can cut anything from prepreg carbon to silk with ease

- Pelican head guides lofted goods through the blade

Video can’t be displayed

This video is not available.

- Smallest and most widely used rotary shear available

- Perfect upgrade to, or replacement for, manual shears

- Streamlined, lightweight construction helps eliminate operator fatigue

- Built-in sharpener

- Equipped with round blade for general use, or optionally with a hexagon or four-sided blade for difficult-to-cut materials

- Newly engineered 220V model with improved electronics

Video can’t be displayed

This video is not available.

This is the ideal companion to any spreading machine for cutting out flaws, or when laying up fabrics.

The handle allows the operator to reach across the table with ease, thereby improving cutting quality.

- Features a long-handle and power switch, in addition to all of the standard D2 features

- Ideal companion to any spreading machine for cutting out flaws, or when laying up fabrics

- Allows the operator to reach across the table with ease, thereby improving cutting capability

Video can’t be displayed

This video is not available.

- Engineered with a 20,000 RPM pneumatic motor

- Eastman’s most powerful rotary shear with the highest torque and greatest RPM

- Optional Pelican head designed for cutting lofted material

- Optional swivel sharpener is equipped with a 30 degree ball tip shear plate for close edge trimming.

Video can’t be displayed

This video is not available.

- Perma-Field Motor for more cutting torque with less heat build-up

- Reliable, versatile and easy to use

- Precision engineered profile and interior reinforcing ribs

- keeps track rigid, even at lengths over 72 inches (1.82 m)

- Add Download Product PDF section using the manual machines catalog

Video can’t be displayed

This video is not available.

Both features enhance cycle time and throughput in comparison to manually-operated models.

The remote control enables the operator to activate the Auto Track Falcon’s cutting cycle as soon as the operator is finished pulling the ply down the table.

- Automatic traversing of the cutting head with an automatic lift feature to enhance cycle time and throughput compared to manual models

- Compression pressure bar ensures a clean cut for both heavy and soft materials

- Remote control enables the operator to activate the cutting cycle as soon as the operator is finished pulling the ply down the table

- Alternative pneumatic head available for heavy-duty cycle environments where frequent starting / stopping is required

Video can’t be displayed

This video is not available.

EASTMAN Heavy Duty Falcon® 548MODEL 548FALHD5H – Featuring Eastman’s Heavy-Duty 548 Cardinal® Round Knife, mounted on a skate and bearing system and inside a track, it is the ideal solution for difficult-to-cut materials or materials that generate debris when being processed.

It can be attached to any type of cutting table with an easy-to-use clamping bracket.

The Heavy Duty Falcon has a “Quick-lift” lifting device allowing for manual spreading and cutting of goods such as heavy woolens, canvas and most industrial fabrics.

- The 548 Falcon has a cutting capacity of 1 inches (2.54cm).

- Cutting of wide material with wide table options (up to 144in. wide / 3.66m wide), with a long handle option or a push/pull handle option for extremely wide cuts needing more than one operator

- Combination of the Cardinal 548 round knife with a heavy duty ball bearing skate and rigid track system, excellent for applications where debris is generated

- Features a “Quick-Lift” device for allowing manual spreading and cutting of goods like heavy woolens, canvas and most industrial fabrics, including composite materials

Video can’t be displayed

This video is not available.

It can be attached to any type of cutting table with an easy-to-use clamping bracket.

The Heavy Duty Falcon has a “Quick-lift” lifting device allowing for manual spreading and cutting of goods such as heavy woolens, canvas and most industrial fabrics.

The 562 Falcon has a cutting capacity of 2 inches (5.08cm).

Cutting of wide material with wide table options (up to 144in. wide / 3.66m wide), with a long handle option or a push/pull handle option for extremely wide cuts needing more than one operator

- Combination of torque and blade speed enables more cutting power for thicker or dense materials

- Large skate with spring loaded bearings to prevent any sway in the cutter during operation

Video can’t be displayed

This video is not available.

The 534 Falcon is suited for light woolens, cotton, silk and synthetics, providing a .5 inch (1.27 cm) of cutting depth.

The 548 Falcon is the choice for woolens, canvas and outerwear materials featuring a cutting capacity of .5 in. – 1 in. (1.27cm – 2.54cm).

- Utilizes the Eastman Cardinal Round Knife models with a special baseplate and handle

- Offers increased cutting capacity

- Higher torque motor for effortless operation

- Cutting head moves easily across the track, reducing operator stress

Video can’t be displayed

This video is not available.

End cutters provide the means to increase speed, efficiency and accuracy in your end cutting operation.

The Falcon Air is perfect for end cutting fusible materials such as heavy rubber and plastic sheeting or for cutting in wet environments where electricity is not applicable.

- Specially designed Falcon track with pneumatic powered cutting head to decrease heat build-up

- Perfect for end cutting fusible materials such as reinforced vinyl and plastic sheeting

- Equipped with a special 3.25 inch (8.25 cm) octagonal blade which creates a chopping action

Video can’t be displayed

This video is not available.

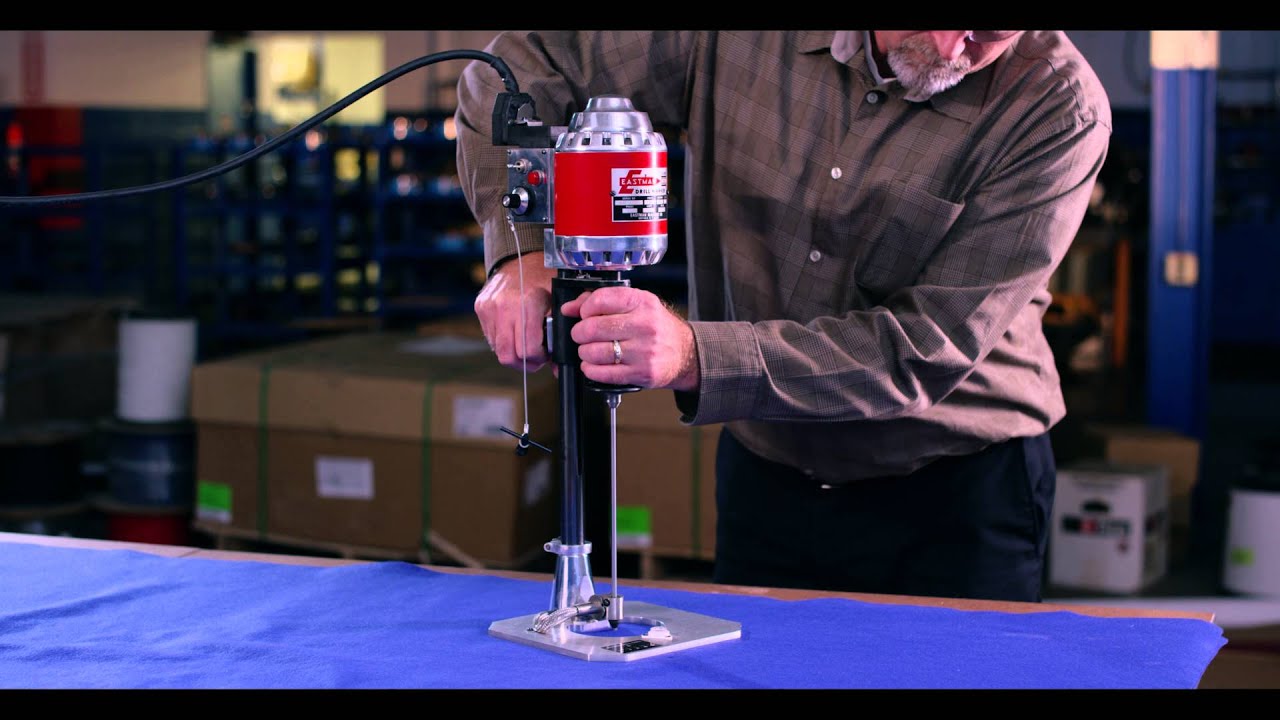

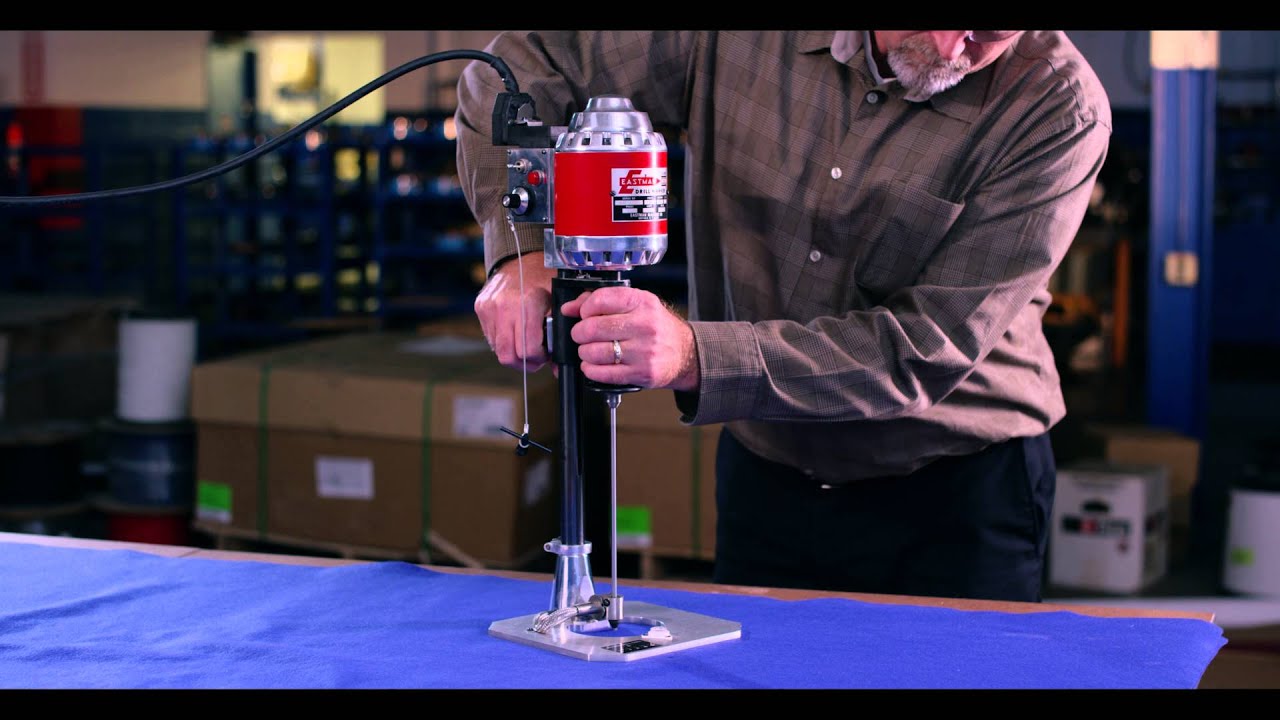

This is perfect for use on loosely knit, bulky, or quilted spreads, where a mark is needed, but where a burn mark would be unnecessary.

- Drills holes through numerous layers of fabric to indicate buttonholes, darts or other markings

- Perfect for use on loosely knit, bulky or quilted spreads where a mark is needed but a burn mark unnecessary

- Telescoping drive shaft and powerful AC motor for dependability and durability

Video can’t be displayed

This video is not available.

The cloth drill fuses tightly woven synthetic materials, throughout the lay, thereby eliminating distortion in the marker.

- Drills holes through numerous layers of fabric to indicate buttonholes, darts or other markings

- Leaves identifiable marks on loosely woven materials or knit fabrics where an ordinary drill mark would not be detected

- Fuses tightly woven synthetic materials throughout the lay, thereby eliminating distortion in the marker

- Variable heat setting

The spread is held securely together and can be moved to the cutting area without shifting.

The Hot Notcher marks a visible notch on materials instead of a slit notch which is not easily visible.

- Multi-purpose tool used for marking and temporarily fusing loosely woven fabrics to ensure alignment for sewing accuracy

- The spread is held securely together and can be moved to the cutting area without shifting

- Marks a visible notch on materials instead of a slit notch which is not easily visible

Utilizing a needle, a thread is pulled through the material which allows the operator to determine where to place pleats, darts, buttons, or pockets.

The Threadmarker LTM can also be used to bundle continuous toweling or bundles of clothes by binding them with thread prior to washing.

- Provides a substitute method of short-term marking when a permanent mark is not desired

- Designed for bundling cut pieces

- Utilizing a needle, a thread is pulled through the material which allows the operator to determine where to place pleats, darts, buttons or pockets

- Ensures matched pairs by eliminating loose cut patterns of varying sizes

- Secures toweling by preventing separation and tangling during the laundering process

- Maximum marking capacity of 6 in. (15.2cm) with simple looper mechanism for ease of operation

- Fully portable, allowing goods to be unrolled directly from the A-Frame to the cutting table

- Maneuverable narrow design with 6 inch (15.2cm) rubber caster wheels

- 1-5/16” rotating roll bars equipped with ball bearing brackets

- Optional cones available

- Optional core reducers available

- Optional heavy-duty 6 roll model available

- Optional heavy-duty 8 roll model available