More than 135 years ago, Eastman introduced the first electric cloth-cutting machine, which allowed the clothing industry to evolve from the manual drudgery of cutting to a modern operation.

Today, the company continues to deliver engineering-based solutions that make real differences to facilities using new and high-tech materials as well as traditional textiles.As a fifth-generation, family-operated business, Eastman is devoted to excellence. Our promise to craft reliable, quality, American-made solutions means that your Eastman product is guaranteed to perform and ensure your production requirements are realized. With our excellent reputation built into every machine, you can rest assured knowing you’re not just buying a product — you’re partnering with a team dedicated to your productivity and performance.

Present Day1000+ automated systems installed worldwide and tens of thousands of manual machines in over 100 countries.

Video can’t be displayed

This video is not available.

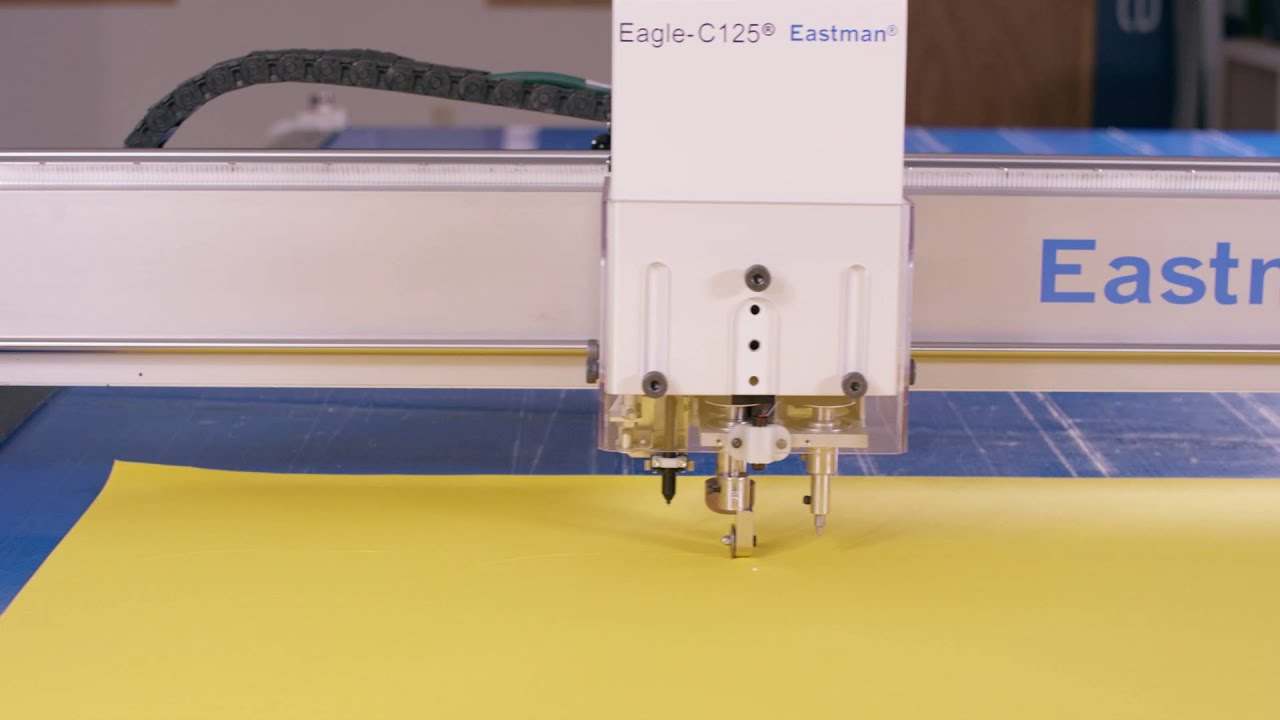

The Eastman Eagle C135 conveyor system boasts supreme capabilities for single- to low-ply cutting requirements. It has the ability to continuously convey rolled material goods with consistent speed and control. Eastman’s gantry and tool head design are engineered to cut the most diverse technical and industrial fabrics available, while exceeding industry standards for accuracy.

The robust conveyor design delivers unrivaled levels of material utilization and is often capable of cutting multiple layers without plastic overlay. This computer-controlled cutting system requires minimal operator guidance to automatically feed and spread material to the identified start position. The C135 offers tremendous efficiency when cutting pattern pieces that exceed the table length. The exclusive InMotion™ software enables the machine to continuously cut while conveying.

Available in a range of widths, lengths and various tool head accessory options, the C135 will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

The robust conveyor design delivers unrivaled levels of material utilization and is often capable of cutting multiple layers without plastic overlay. This computer-controlled cutting system requires minimal operator guidance to automatically feed and spread material to the identified start position. The C135 offers tremendous efficiency when cutting pattern pieces that exceed the table length. The exclusive InMotion™ software enables the machine to continuously cut while conveying.

Available in a range of widths, lengths and various tool head accessory options, the C135 will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

EASTMAN L135 Laser SystemThe L135 mounts to the gantry of a static or conveyor table, allowing quick transition from traditional cutting to laser cutting.

Eastman’s gas assist, class 4 laser cuts and seals material edge simultaneously with unmatched precision. Make detailed cuts without physical contact, reducing defects from wrinkling and pulling. The L135 laser mounts to the gantry of a static or conveyor table, allowing quick transition from traditional cutting to laser cutting. Marking and labeling tools, or any other tool head options, can be added. Please contact the factory for CL135 conveyor technical specifications.

Various laser wattage configurations are available: 50, 60, 80, 100, or 120 watts. The ceramic core is durable and provides optimal laser stability while cutting, engraving, or perforating.

Various laser wattage configurations are available: 50, 60, 80, 100, or 120 watts. The ceramic core is durable and provides optimal laser stability while cutting, engraving, or perforating.

Video can’t be displayed

This video is not available.

EASTMAN S135 Static Table Cutting SystemSingle- to low-ply precision cutting, marking, and punching of any flexible material with Eastman’s S135 static table. Multiple cutting surfaces are available to suit various cutting applications.

S135 – Static Table System

Eastman’s static table system is capable of cutting, marking and punching virtually any flexible material at speeds of up to 60 inches per second (152.4 cm/sec.). The static cutting table has proven itself as the go-to resource for materials like cotton, nylon and vinyl as well as difficult-to-cut materials—such as polystrand, p-tex, and fiberglass-polyester blends.

The system’s high-precision configuration features multi-axis motion for more defined and accurate cuts. Material is spread across the static table by an operator or with the use of a pneumatic gripper bar. The open plenum vacuum system design ensures evenly dispersed airflow for optimal material hold-down. This computer-controlled system features zoning capabilities to enable cutting in one area while the operator is simultaneously picking parts in another, maximizing daily production capacity.

The static table system is available in a range of system lengths and widths to meet the demands for prototypes, one-offs and full-production runs.

The system’s high-precision configuration features multi-axis motion for more defined and accurate cuts. Material is spread across the static table by an operator or with the use of a pneumatic gripper bar. The open plenum vacuum system design ensures evenly dispersed airflow for optimal material hold-down. This computer-controlled system features zoning capabilities to enable cutting in one area while the operator is simultaneously picking parts in another, maximizing daily production capacity.

The static table system is available in a range of system lengths and widths to meet the demands for prototypes, one-offs and full-production runs.

Video can’t be displayed

This video is not available.

EASTMAN Talon Multi-PlyThe Talon offers an industrial-strength solution for high-ply production facilities with capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Eastman Talon Multi-Ply is engineered and manufactured in the USA to automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Precise system operations with state-of-the-art motion control communications offer an industrial-strength solution. The Talon 25x can cut up to 1.18 in. (3 cm) of compressed material goods, while the Talon 75x has the capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Talon has been engineered to meet the demands of clients in growing market segments like industrial fabrics and composites industries; customers cutting traditional -as well as- modern technical materials like kevlar, fiberglass, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

The Talon has been engineered to meet the demands of clients in growing market segments like industrial fabrics and composites industries; customers cutting traditional -as well as- modern technical materials like kevlar, fiberglass, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

Video can’t be displayed

This video is not available.

EASTMAN HawkThe Hawk is a high-speed, precision cutting system with a multi-functional tool head. It is a modern solution specific to professionals working in the advanced printing, packaging and graphics sector as well as industrial applications like gaskets, foam and insulation which require special cutting applications.

- Eastman’s Hawk offers high-speed, precision cutting, impressing with its functional design and concentration on the basic essentials:

- Freely accessible work surface from all sides

- Extremely robust traverse bridge with minimal protruding at the sides and rack and pinion drive system in all axis for slip-free drive.

- Powerful AC-servo motors and modern CAN-Bus-steering technique enable high throughput

EASTMAN Combi Laser - Cutting Static TableThe Combi Laser is a proven solution to cut and fuse the edge of fabric using Eastman’s static table and a heavy duty tool head equipped with a 200-watt gas assist laser.

Video can’t be displayed

This video is not available.

Product SummaryThe Eastman combination laser and cutting system offers a laser for cutting fabrics that require a fused edge as well as the proven, reliable technology of Eastman’s static cutting table. The tool head is equipped with a 200 watt gas assist laser (100 watt optional), three individually aligned and calibrated tool spindles, and a pneumatic pen/marker holder.

EASTMAN Ultrasonic Tool HeadThe Ultrasonic Tool Head option has been designed for cutting adhesive-backed, composite, or gasket type materials with 20,000 oscillations per second. The ultrasonic technology reduces blade gumming and friction between the material and blade.

Video can’t be displayed

This video is not available.

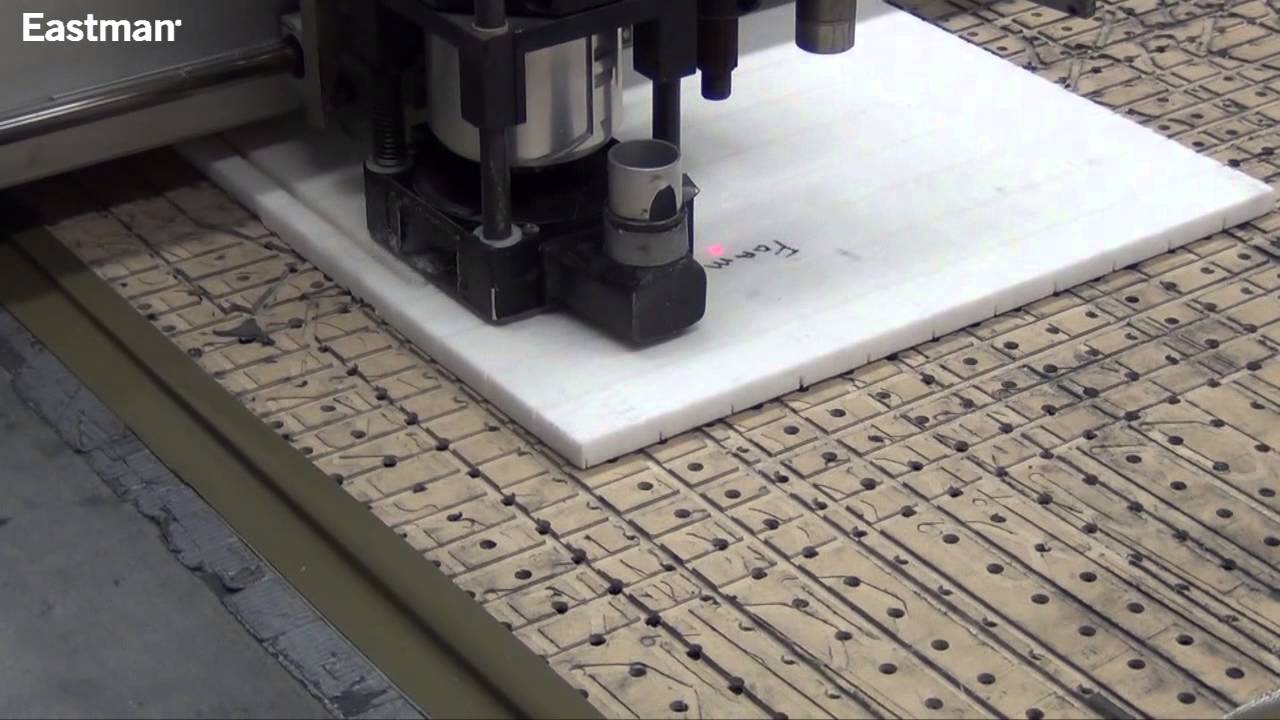

EASTMAN Combi Router - Cutting SystemEastman’s router tool head option offers a two-spindle tool head in addition to the router for a variety of cutting and routing options. It features a pneumatically controlled z-axis and a manually adjustable depth-control function.

Eastman’s router tool head option delivers heavy-duty performance for thick and dense materials. This system offers a two-spindle tool head in addition to the router for a variety of cutting and routing options. Features such as a pneumatically controlled z-axis and a manually adjustable depth-control function facilitate cutting materials such as soft or hard wood, composites, fiberboard, and a variety of plastics. A large-capacity debris-collection system helps create a clean work environment.

Available in a range of widths, lengths and various tool head accessory options, the S125 with laser will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

Available in a range of widths, lengths and various tool head accessory options, the S125 with laser will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

- Single- or low-ply layer cutting.

- Two spindle tool holders and a router.

- Exclusive carbon impregnated anti-static fiber belt for long life and cutting quality

- Sacrificial routing surface

- Large capacity router debris collection system.

- Available add-on for the conveyor or static table cutting systems

EASTMAN EasiMark™Simplify part identification with Eastman’s innovative airbrush marking system, EasiMark.

Eastman’s innovative airbrush marking system, EasiMark, can be added as a convenient option to the tool head to simplify part identification.

Airbrushing is especially useful for fabrics such as fiberglass and other materials where traditional printing will not work. EasiMark’s non-clogging ink is fed from a reservoir mounted on the tool-head. Air pressure sends the ink to an industrial spray head and onto the material.

Permanent and washable inksAvailable in single or dual airbrush configurationsThe marking system can be conveniently added to the S125 or C125 gantries.

Airbrushing is especially useful for fabrics such as fiberglass and other materials where traditional printing will not work. EasiMark’s non-clogging ink is fed from a reservoir mounted on the tool-head. Air pressure sends the ink to an industrial spray head and onto the material.

Permanent and washable inksAvailable in single or dual airbrush configurationsThe marking system can be conveniently added to the S125 or C125 gantries.

- Reduced labor time in collecting parts

- Easy identification of parts

- Simplified system set-up and clean-up

- Permanent and washable inks available

- Available in single or dual airbrush configurations

EASTMAN JetPRO HRJetPRO HR is a thermal inkjet drop-on-demand printer that allows full-speed character printing. JetPRO is the answer to fast throughput printing, compared to a more traditional pen or airbrush marking options.

JetPRO™ HR is a thermal inkjet drop-on-demand printer that allows full speed character printing with an ink color and formula available for most surfaces.

It is an optional gantry mounted upgrade for the conveyor and static table systems.

JetPRO is the answer to fast throughput printing compared to more traditional pen or airbrush marking options.

It is an optional gantry mounted upgrade for the conveyor and static table systems.

JetPRO is the answer to fast throughput printing compared to more traditional pen or airbrush marking options.

- Thermal Inkjet drop-on-demand printing

- Maximum resolution 600 x 600 dpi

- Fixed line speed for all fonts

- Various compatible linear, 2D, Uni codes; Supports TrueType® Fonts

- Nominal character height from up to 1/2 in (12.70mm) – Single print head

- Printing at 0°,45°, 90°, 135°, 180°, 225°, 270°, 315°angles

- Character sets and interface options available in multiple languages

- Simple ink cartridge system requires minimal maintenance

- Black ink cartridge supplied as standard

- Reduces addressable cutting length by 1 ft. (0.30 meters)

- Available on static and conveyor systems

Video can’t be displayed

This video is not available.

EASTMAN EasiHold™Eastman’s EasiHold™ dynamic vacuum compressor is an integral part of the C125 Fiber Cutting System, allowing users to cut lofted material, such as fiberfill and foam, with unparalleled speed and ease.

Eastman’s EasiHold™ dynamic vacuum compressor holds down thick, porous material using a tough plastic overlay for easy cutting. EasiHold is an integral part of the Conveyor – Fiber Cutting System, allowing users to cut lofted material, such as fiberfill and foam, with unparalleled speed and ease.

- EasiHold is an optional feature for the C125 conveyor system only

- Plastic overlay curtain is never cut, eliminating consumable waste

- For additional technical specifications, please see the C125 conveyor system.

Video can’t be displayed

This video is not available.

EASTMAN SLS3 Stack LabelerThe Eastman SLS3 stack labeler fully automates the labeling process, reducing time, labor, and costly operator errors.

The Eastman SLS3 stack labeler fully automates the labeling process, reduces time, labor and eliminates costly errors that can occur with manual labeling. The SLS3 operates on all standard spreading tables and can interface with any CAD system.

The SLS3 replaces large paper patterns or markers used for identification purposes with small, adhesive labels. Accurately print and affix pattern labels to the top layer of fabric stacks up to 4 inches (10.16cm) high. The stacks are then ready to move to a high-ply cutting system where they are cut and bundled.

The SLS3 replaces large paper patterns or markers used for identification purposes with small, adhesive labels. Accurately print and affix pattern labels to the top layer of fabric stacks up to 4 inches (10.16cm) high. The stacks are then ready to move to a high-ply cutting system where they are cut and bundled.

- Prints and applies labels in one step

- Thermal print head

- Adjustable speed control

- Standard label sizes: 1 in. x 2 in. or 1.25 in. x 0.5 in.

- Supports numbers 0-9; characters A-Z; +/-/./$/% and SPACE

- One of seven available barcode types may be selected (standard is CODE39)

- Accommodates 9 information fields in various font sizes

- Operates on all standard spreading tables

EASTMAN LabelPRO

Eastman’s LabelPRO system is for simple pattern identification. Integrated with the cutting tool head, a printhead is used to print and place self-adhesive labels onto pattern pieces as they are cut. LabelPRO reduces the time & effort required to manage cut pieces.

Eastman’s LabelPRO™ system is for simple pattern identification. Integrated with the cutting tool head, a printhead is used to print and place self-adhesive labels onto pattern pieces as they are cut. LabelPRO™ reduces the time & effort required to manage cut pieces. Label data comes directly from a CAD pattern database and can be barcoded or printed with multiple fonts.

Eastman’s label system reduces the time and effort required to manage cut pieces.

Eastman’s label system reduces the time and effort required to manage cut pieces.

- Printhead / label sizes available: 2 in. x 1 in. and 1.25 in. x 5 in.

- Maximum character count is 13 for a 2 in. wide label

- Supports numbers 0-9; characters A-Z (capital letters only); +/-/./$/% and SPACE

- One of seven available barcode types may be selected (standard is CODE39)

- 5,500 labels per roll